The primary purpose of the food and beverage industry is to transform raw agricultural products into consumable food and drink items, ensuring they are safe, nutritious, and appealing to consumers.

It is severely critical that the food and beverage industry fulfill its primary purpose. The industry's specialized demands are being satisfied by our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp, which are imperative critical assets. This process commands high optimization, dependability, versatility, and reliability to ensure personnel safety and equipment integrity. Our UNICLAMP clamps fulfill these requirements.

The Key Stages of the Food and Beverage Industry Process

Agricultural Production: Farming and Harvesting

Raw Material Handling: Transportation and Storage

Processing: Initial, Primary, and Secondary processing

Packaging: Packaging design and Filling and Sealing

Quality Control and Safety: Testing and Inspection

Distribution: Logistics and Cold Chain Management.

Marketing and Sales: Product Development, Branding, and Advertising including Retail and Food Service

Consumption: Purchase, Preparation, and Consumption

Waste Management: Recycling, Composting and Disposal.

Each stage involves meticulous planning, coordination, and regulation to ensure the final products are safe, high-quality, and meet consumer expectations.

Uses and Advantages of Our Uniclamp Strut Pipe Clamp and V-BAT™ Pipe Clamp

Our UNICLAMP Pipe Clamps are applied when high mechanical strength, solidness, exceptional stability, pressure, temperature variations, and corrosive resistance are required.

Universal Fit and Compatibility

Our UNICLAMP strut pipe clamp and V-BAT™ pipe clamp are designed to accommodate a wide range of pipe sizes, from 3/8" to 5" (9 mm up to 127 mm)

Our UNICLAMP Pipe Clamp’s design makes it compatible with an assortment of pipe and fastener materials: Stainless Steel, Brass, Copper, Polyvinyl Chloride (PVC), Chlorinated Polyvinyl Chloride (CPVC), High-Density Polyethylene (HDPE), Polypropylene (PP) and Teflon (PTFE) used in the food and beverage industry. The demanding conditions of this industry make our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp the absolute fastener choice. This compatibility guarantees that the same clamp can be used throughout all pipe installations, eliminating the complexity of procurement and inventory management Whether used for Small, Medium, or Large Diameter Pipes, our UNICLAMP Strut and Our V-BAT™ Pipe Clamps will handle it all.

The Main Pipelines utilized by the Food and Beverage Industry

Main Pipelines transport the following food products, Water, Milk, Juice, Beverage, Oil and Fat, Dairy Products, Liquid Sugar, Wine, Spirits, Beer, Soup, Sauce, Chocolate, Confectionery, Fruit, Vegetable Puree, and Condiment

These pipelines transport potable water, raw and pasteurized milk, freshly squeezed juice, juice concentrates, soft drinks, carbonated beverages, alcoholic beverages, syrups, and flavorings, vegetable oils, animal fats, and other edible oils, liquid dairy products like yogurt, cream, and buttermilk, cheese curds, liquid sugar or syrups, high-fructose corn syrup, and other sweeteners, wine, distilled spirits, wort, finished beer, liquid soups, sauces, broths, liquid chocolate, confectionery ingredients, pureed fruits and vegetables, liquid condiments like ketchup, mustard, and salad dressings.

Commonly Used Fasteners in The Food and Beverage Industry

Pipe, Hygienic Pipe, Vibration Damping, U-Bolt, Cushion, Strut, Hanger, Split Ring, Tri-Clamp Fittings, and Saddle Clamps.

These are some competitor clamps U-Bolt, Cushion Clamps, Strut Clamps, Hanger Clamps, and Saddle Clamps used to secure the fourteen mentioned pipelines. Our UNICLAMP Strut and V-BAT™ Pipe Clamps can replace all these fasteners, with numerous benefits compared to competitor clamps.

Compared to various types of pipe-securing hardware, our UNICLAMP Pipe Clamps are significantly more cost-effective.

Check out our Uniclamp Blogs here to see the other clamps that Our Uniclamp and V-BAT™ Pipe Clamps replace.

Durability and Non-Corrosiveness of Our Pipe Clamps

Manufactured from 30% glass-reinforced nylon 6.6, both Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp boast tensile strengths of 8700 - 12300 psi (900 lbs and 1100 lbs) respectively, making them desirable for inhospitable conditions. Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are highly durable, demonstrating superior tensile robustness and steadiness. Our Pipe Clamps are non-receptive to rust, water, acid, alkalines, and any type of corrosion. Additionally, they provide wear and tear and dimensional stability, making them a must for humid and corrosive environments. Our UNICLAMP Clamps have smooth surfaces and are easy to clean to prevent bacterial growth. This durability results in fewer replacements and lower maintenance costs, saving money and time. Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp UV resistance guarantees a lifespan of 15-20 years, even in rigorous environments, eliminating the need for UV-resistant coatings and materials to protect pipeline fasteners.

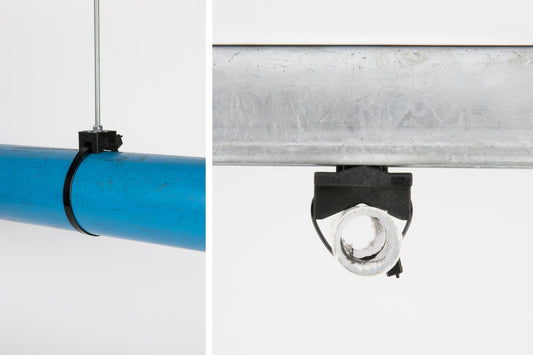

Pipe installations implement heavy-duty strapping offering stability, strength, and endurance. Stainless steel strapping can support up to 200 lbs, with thickness varying based on specific installations. Our nylon cable ties, made from UV-stabilized nylon 6.6, have a carrying capacity of up to 175 lbs. Our clamps and ties are specifically designed to ensure that pipes are securely held in place at all times, which is essential in the food and beverage industry.

For more information on Strapping and Zip-tie options please check out our blog.

Chemical Exposure

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are acid resistant and 95% to most common chemicals guarantee no deterioration of our clamps when directly exposed to alkalines and acids. There are no visible signs of degradation or permanent chemical changes. Our UNICLAMP clamps are tremendously resistant to the 41 (Forty-One) chemicals utilized in the food and beverage Industry. These chemicals hold no match to our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp.

Certifications

Our UNICLAMP Strut V-BAT™ Pipe Clamps are certified by UL2239, UL2043, ISO, RoHS, Reach, and Branz, providing confidence and assurance.

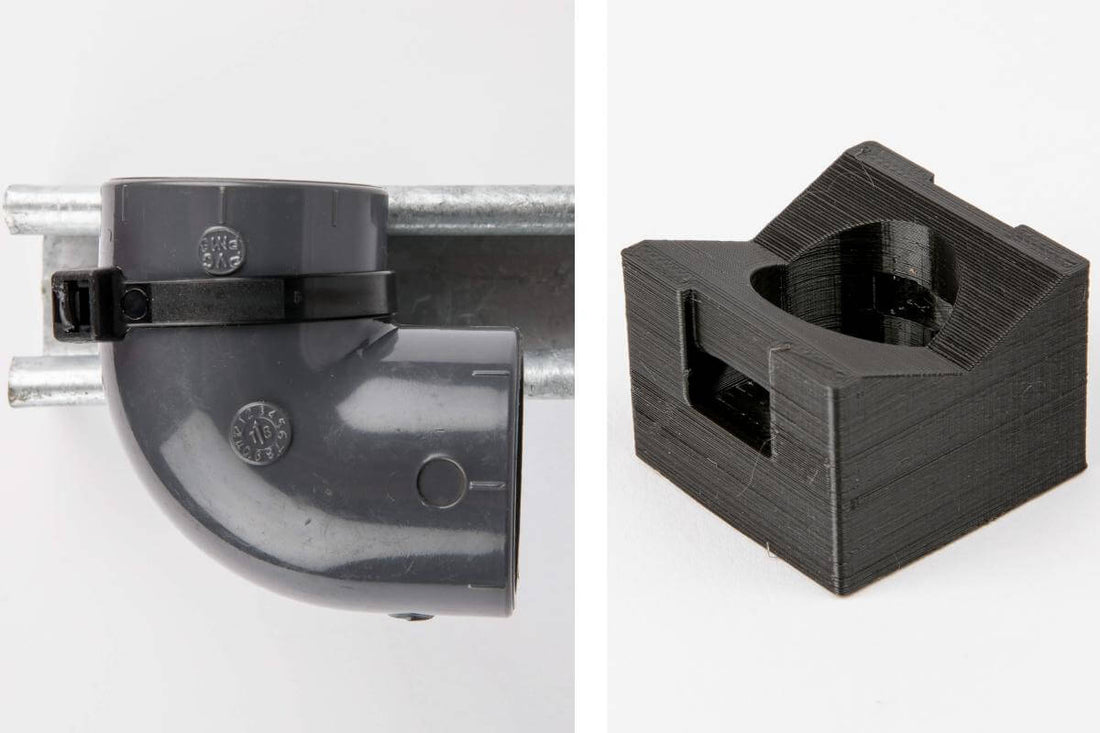

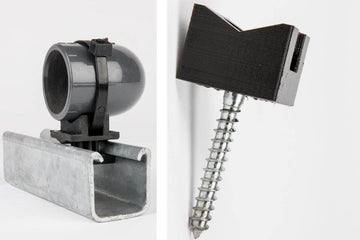

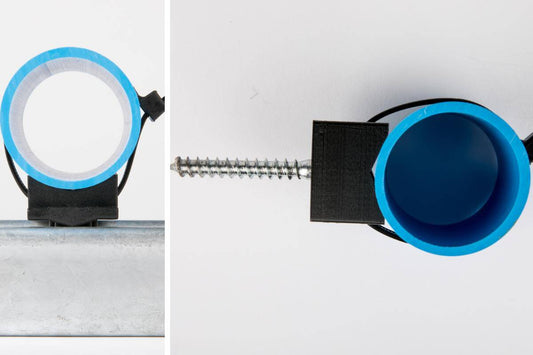

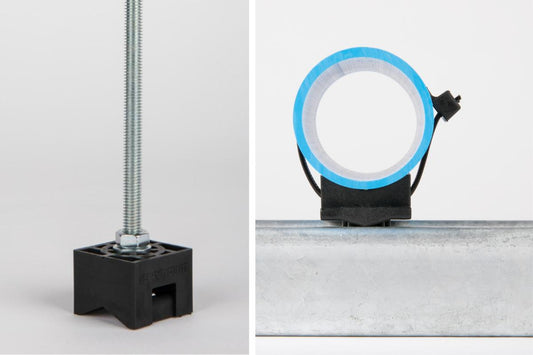

V-BAT™ Pipe Clamp

Our V-BAT™ Pipe Clamp is Compatible with Hilti tools for fast and effective concrete and surface installations, Our V-BAT™ Pipe Clamp's robustness is evident by not displaying any fractures, shattering, or weakening, proving its capacity for heavy-duty applications. A socket wrench or ratchet is another option for simply installing Our V-BAT™ Pipe Clamp, facilitating quick setups and reducing labor expenses. The V-BAT™ Pipe Clamp offers versatile applications: flat surfaces, universal hangers, spacers, and Unistrut fixtures.

For more information on the numerous applications of Our V-BAT™ Pipe Clamps check out Our Blog.

UNICLAMP Strut Pipe Clamp

Our UNICLAMP Strut Pipe Clamp cuts installation time by up to 83% compared to conventional clamps. We are featuring an uncomplicated tool-free, place, twist, and strap interlocking system, a cost-effective option for all projects. This clamp can also be mounted as a hanger clamp on Unistrut.

Our HDPE Sleeve is designed to prevent damage to pipe insulation. HDPE Sleeve Insulation is often employed to avoid cross-contamination and reduce temperature impacts on transport pipes, particularly in extreme climates.

For more information on Our HDPE Sleeve check out Our Blog called Enhancing HVAC System Performance with V-BAT Pipe Clamps and HDPE Sleeves.

Temperature Resistance of our Our UNICLAMP Strut and V-BAT™ Pipe Clamps

Minimum Service Temperature of -22°F to 266°F (-30°C to 130°C) and Maximum Service temperatures of 149°F - 550°F (65°C - 288°C) (MatWeb) qualify our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp to be safely used in the food and beverage industry environment, offering great resistance to creep.

For more information on Our Uniclamp Strut Pipe Clamp check out Our Blog.

The Food and Beverage Industry operates under various temperatures, pressures, and vibration levels depending on the specific processes involved.

Temperatures

Refrigeration and Freezing: 32°F to 39°F (0°C to 4°C) and 0°F to -31°F (-18°C to -35°C)

Pasteurization: 145°F (63°C), 161°F (72°C) and 275°F to 302°F (135°C to 150°C)

Sterilization: 250°F (121°C)

Cooking and Baking: 350°F to 450°F (175°C to 230°C) and 350°F to 375°F (175°C to 190°C)

Brewing: 140°F to 158°F (60°C to 70°C) and 212°F (100°C)

Chocolate: 82°F to 90°F (28°C to 32°C)

Pressures

Beverage Carbonation: 15 to 30 psi (1 to 2 bar)

Dairy Processing: 2000 to 3000 psi (138 to 207 bar)

Steam Cooking and Sterilization: 15 psi (1 bar) up to 30 psi (2 bar)

Pump and Pipeline Pressures: 20 to 100 psi (1.4 to 7 bar)

Vibrations

Machinery and Equipment: 0.1 to 5.0 mm/s RMS

Conveyors and Packaging Lines: 2 to 2.5 mm/s RMS.

Corrosion

Corrosion is a significant concern in the Food and Beverage Industry due to the potential impact on equipment integrity, product quality, and safety.

Types of Corrosion:

Uniform, Pitting, Crevice, Galvanic, Stress Corrosion Cracking (SCC), Intergranular, Chloride, High humidity levels, Hard and Soft water, High flow rates, Stagnant conditions, and Acid (pH < 2.0) and Alkalis (pH > 11.0) Corrosion.

As proven, our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp do not accommodate any corrosion or pitting.

The UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp

Our UNICLAMP Strut and V-BAT™ pipe clamps are highly versatile products securing pipes, conduits, and tubing to various structures.

The food and beverage industry depends heavily on piping systems to transport numerous products. Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp provide a tested and tried method of securing pipes, hoses, and equipment to walls, ceilings, and concrete floors. Its robust construction ensures that pipes remain unmoveable, preventing leaks and maintaining the system's integrity.

The Uniclamp Strut and the V-BAT™ pipe clamps allow for trouble-free adjustments. This flexibility is crucial in a manufacturing setting where changes in the process might require repositioning or adding new piping. The clamp’s design and functionality ensure these modifications are made without extensive downtime.

Safety and Efficiency

The safety and efficiency of the food and beverage process are crucial. Both our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp contribute unquestionably to these aspects in several ways:

Leak Prevention: Securely fastened pipes are less likely to leak, crucial in maintaining the quality and consistency of raw material and the finished product. Leaks also pose safety hazards and result in wastage of valuable resources. Employees could be exposed to chemical burns, heat and steam burns, and chemicals. Wet and slippery floors create the possibility of slips and falls:

Ease of Maintenance: Installation of these clamps ensures that maintenance on pipes and equipment is performed rapidly and efficiently. This reduces downtime and ensures that manufacturing operates smoothly. Note that all UNICLAMP pipe clamps are maintenance-free.

Strength and Reliability: The robust construction of the UNICLAMP Strut and the V-BAT™ Pipe Clamps ensure withstanding the demanding conditions of the manufacturing operations. This reliability ensures the infrastructure remains safe and functional, protecting the product and personnel.

Corrosion Resistance: Food and beverage manufacturing deals with constant humid environments and chemical exposure. Eliminating protective coatings, regular maintenance, and corrosion Inhibitors our UNICLAMP clamps are up for the challenge!

Conclusion

Ensuring safety and efficiency in the Food and Beverage industry is paramount for sustainability and productivity. Understanding and managing the primary goals of the Food and Beverage Industry, longevity and safety of equipment, shall guarantee product quality.

Utilization of our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp enhances productivity and safety, understanding that these aspects are not negotiable. Our UNICLAMP clamps proudly contribute.

For more information on Our Uniclamp products, please visit our website