The primary purpose of the automotive industry is to design, develop, manufacture, market, and sell motor vehicles.

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are imperative and indispensable assets that fulfill the precise unique demands of the automotive industry. Vigorousness and Diverseness are requirements this industry emphasizes. This process commands high levels of optimization and credibility to ensure personnel safety and equipment integrity. Our UNICLAMP clamps fulfill all of these requirements.

Process of the Automotive Industry

Research and Development (R&D): Prototypes undergo rigorous safety, performance, and durability testing.

Design: Integration of mechanical, electrical, and software components.

Manufacturing: Each vehicle undergoes stringent quality checks to meet safety and performance standards.

Supply Chain Management: Efficient logistics ensure timely delivery of raw materials and parts to manufacturing plants.

Marketing and Sales: Understanding consumer needs and market trends.

After-Sales Service: Offering assistance and addressing customer concerns.

Regulations and Compliance: Adhering to safety regulations and conducting crash tests.

Electric Vehicles (EVs): Increasing focus on electric and hybrid vehicles.

Autonomous Vehicles: Development of self-driving cars with advanced sensors and AI.

Connected Cars: Integration of Internet and communication technologies.

Sustainability: Efforts to make the production process and end products more sustainable and environmentally friendly.

Pipes used in The Automotive Industry

In service bays, workstations, and production lines within the automotive industry, a sophisticated system of pipes is designed to safely and efficiently transport numerous products.

These include the following pipes:

Hydraulic Oil, Compressed Air, Water, Waste Oil, Coolant, Lubricants, Vacuum Lines and Gas Pipes

These pipes transport the following essential products and utilities:

Hydraulic oil, Air for powering pneumatic tools, inflating tires, and operating some types of lifts, Water for cleaning vehicles and parts and for cooling systems, waste oil for proper disposal or recycling, Coolant for filling and topping up vehicle cooling systems, transport motor oil, transmission fluid, and other lubricants, Vacuum lines are installed to provide suction power for vacuum-assisted tools and equipment. Supply oxygen, acetylene, and nitrogen.

Fixed and Mobile Robots Used in The Automotive Industry

In the automotive industry, robots (cobots or collaborative robots) require various types of pipes and cables. The routing and installation of these pipes and cables are critical for ensuring the smooth operation of both fixed and mobile robots while maintaining safety and efficiency in the workspace.

Types of Pipes and Cables used by Robots:

-

Power and Data Cables

-

Hydraulic Pipes

-

Pneumatic Pipes

-

Cooling Pipes

-

Lubrication Pipes

These cables and pipes are mounted on floors, attached to walls, and beams, and suspended from ceilings providing connection points and proper support.

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp persuasively optimize the securing of these pipes and cables.

Uses and Advantages of Our Uniclamp Strut Pipe Clamp and V-BAT™ Pipe Clamp

The primary purpose of our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp is to produce high mechanical shear force, robustness, exceptional consistency, and corrosive resistance.

Universal Fit and Compatibility

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are designed to accommodate a wide range of pipe sizes, from 3/8" to 5" (9 mm up to 127 mm)

Our UNICLAMP Pipe Clamp’s unique design makes it compatible with an assortment of pipe and fastener materials: Galvanized Steel, Carbon Steel, Stainless Steel, Plastic (PVC, CPVC, PEX, and Polyethylene), Aluminum, Copper, Rubber and Synthetic Hoses, Composite Materials and Forged steel used in the automotive industry. Our UNICLAMP Strut and V-BAT™ Pipe Clamps are the ideal fastener choice to accommodate the specific robust conditions of this manufacturing environment. This compatibility ensures that the same clamp can be used throughout all pipe installations, simplifying inventory management and procurement. Whether utilized for small or larger pipe installations, Our UNICLAMP Strut and Our V-BAT™ Pipe Clamps will handle it all.

Durability and Non-Corrosiveness of Our Pipe Clamps

Both Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamps are manufactured from 30% glass-reinforced nylon 6.6, with tensile strengths of 900 lbs and 1100 lbs (8700 - 12300 psi) respectively, making them suitable for unyielding conditions. Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are tremendously solid, exhibiting superior mechanical tensile strength and resilience. Our Pipe Clamps are extremely resistant to rust, water, acid, alkaline, and all corrosion. Additionally, they provide wear and tear resilience and dimensional stability, making them exemplary for humid and corrosive environments. Our UNCLAMP clamps are effortlessly cleaned preventing mold and bacteria growth. Saving money over time, this durability leads to fewer replacements and lower maintenance costs. Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp UV resistance guarantees a lifespan of 15-20 years, even in extreme environments, eliminating the need for UV-resistant coatings and materials to protect pipeline fasteners.

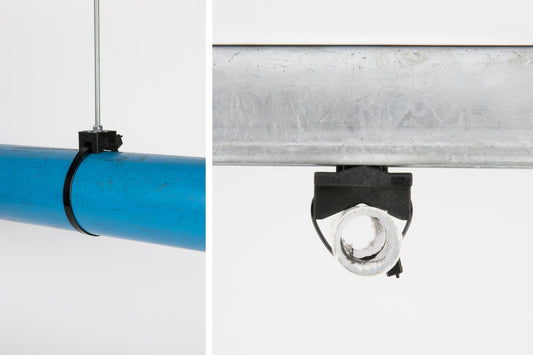

Pipe installations implement heavy-duty strapping offering stability, strength, and endurance. Our nylon cable ties, made from UV-stabilized nylon 6.6, have a carrying capacity of up to 175 lbs. Stainless steel strapping can support up to 200 lbs, varying thickness based on specific installations. Our clamps and ties are specifically designed to ensure that pipes are securely held in place at all times, which is crucial in the automotive industry

For more information on Strapping and Zip-tie options please check out our blog.

Chemical Resistance

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are acid and alkaline-resistant and 95% to most common chemicals guaranteeing no deterioration of our clamps when directly exposed. No visible signs of degradation or structural chemical changes are evident.

The 36 (Thirty-six) chemicals used in the automotive industry hold no match to our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp.

Certifications

Our UNICLAMP Pipe Clamps are certified by UL2239, UL2043, ISO, RoHS, Reach, and Branz, providing confidence and assurance.

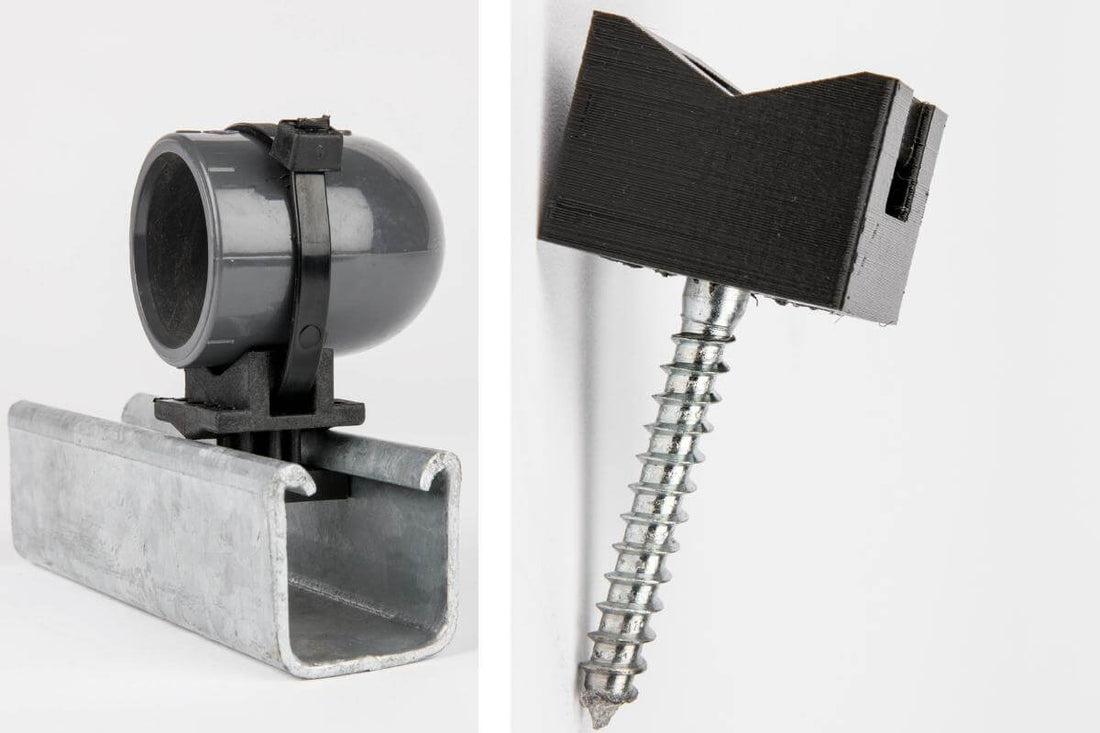

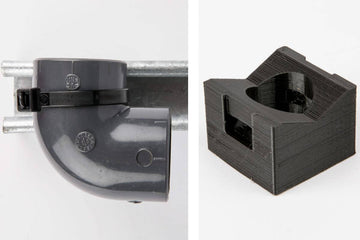

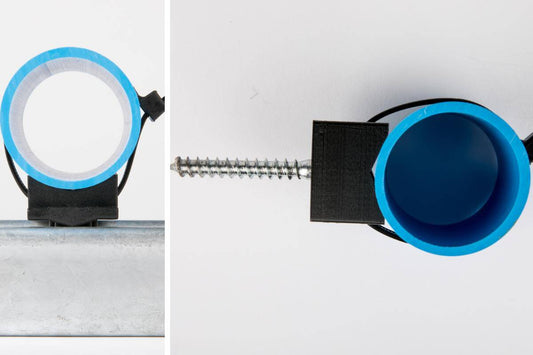

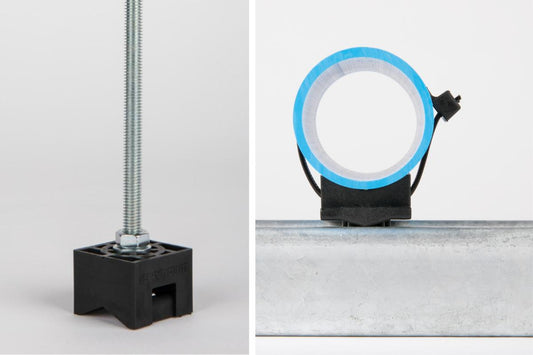

V-BAT™ Pipe Clamp

When used with a Hilti gun, our V-BAT™ Pipe Clamp's robustness is proven by not displaying any fractures, shattering, or weakening, validating its capacity for heavy-duty applications. A socket wrench or ratchet is another option for simplifying the installation of our V-BAT™ Pipe Clamp, facilitating quick setups, and reducing labor expenses. The V-BAT™ Pipe Clamp offers versatile applications: flat surfaces, universal hangers, spacers, and Unistrut fixtures.

For more information on the numerous applications of Our V-BAT™ Pipe Clamp check Our Blog.

UNICLAMP Strut Pipe Clamp

Our UNICLAMP Strut Pipe Clamp cuts installation time by up to 83% compared to conventional clamps. Featuring a tool-free, simple place, twist, and strap interlocking system, a cost-effective option for all projects. This clamp can also be mounted as a hanger clamp on the Unistrut.

Our HDPE Sleeve is designed to prevent damage to pipe insulation. HDPE Sleeve Insulation is often employed to avoid cross-contamination and reduce temperature impacts on transport pipes, particularly in extreme climates.

For more information on Our HDPE Sleeve visit Our Blog called Enhancing HVAC System Performance with V-BAT Pipe Clamps and HDPE Sleeves.

Temperature Resistance of Our UNICLAMP Strut and V-BAT™ Pipe Clamps

Minimum Service Temperature of -22°F to 266°F (-30°C to 130°C) and Maximum Service temperatures of 149°F - 550°F (65°C - 288°C) (MatWeb) authorizing Our UNICLAMP Strut and V-BAT™ Pipe Clamps to be safely and risk-free used in the automotive industry, offering great resistance to creep.

For more information on Our Uniclamp Strut Pipe Clamp check out Our Blog.

Temperatures, Pressures and Vibrations Present in The Automotive Industry

Temperatures, pressures, and vibrations encountered in automotive service bays, workstations, and production lines vary widely depending on the specific activities and equipment used.

Temperatures

Engine Operating Temperature: 190°F to 220°F (88°C to 104°C)

*Exhaust Systems: 1300°F to 1600°F (700°C to 870°C).

*Welding Torches: 6000°F (3316°C).

*Cutting Torches: 6000°F to 8000°F (3316°C to 4426°C).

Engine Oil:175°F to 250°F (75°C to 121°C).

Coolant Systems:195°F to 220°F (90°C to 104°C).

* Note: Our clamps are restricted in design to withstand such direct elevated temperatures

Pressures

Tire Inflation: 30 to 35 psi and 80 to 100 psi.

Hydraulic Systems: 1,500 to 3,000 psi.

Brake Systems: 800 to 2,000 psi.

Fuel Systems: 30 to 100 psi for gasoline engines and 30,000 psi for diesel engines.

Air Conditioning Systems: 25 to 400 psi

Vibrations

Power Tools: vibration levels 2 to 10 m/s2

Engine and Transmission Testing: 1 to 50 Hz.

Vehicle Lifts: below 1 Hz

Air Compressors and Pumps: 20 to 200 Hz.

Our UNICLAMP Strut and V-BAT™ Pipe Clamps absorb all pressures and vibrations, showing no compressive stress. Therefore Installing vibration-damping mounts, pads, and vibration monitoring is not required, saving time and money.

The UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp

Our UNICLAMP Strut and V-BAT™ pipe clamps are highly versatile products securing pipes, conduits, and tubing to various structures.

The automotive industry relies absolutely on piping systems to transport numerous critical products. Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp provide a tested and tried method of securing pipes, hoses, cables, and equipment to walls, ceilings, concrete floors, beams, and struts. Its vigorous construction guarantees that pipes remain unmoveable, averting leaks and maintaining the system's integrity.

The Uniclamp Strut and the V-BAT™ pipe clamps allow for trouble-free adjustments. This flexibility is crucial in the industry where changes in the process might require repositioning or adding new piping. The clamp’s design and functionality ensure these alterations are made without extensive downtime.

Safety and Efficiency

The safety and efficiency of the automotive industry are paramount. Both our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp contribute audaciously to these attributes in various ways:

Leak Prevention: By properly securing pipes in automotive assembly lines, the efficiency and safety of the production process are maintained, reducing the risk of leaks, breaks, and other potential hazards. Leaks pose safety hazards and result in wastage of valuable resources. Coming in contact with or inhaling chemicals such as solvents, gasoline, oils, and other automotive fluids could result in skin irritation or allergic reactions. Leaks are attributed to the potential for fire hazards. Wet and slippery floors create the possibility of slips and falls:

Ease of Maintenance: Installation of these clamps ensures that maintenance on pipes and equipment is performed rapidly and efficiently. This reduces downtime and ensures that manufacturing operates smoothly. Note that all UNICLAMP pipe clamps are maintenance-free.

Strength and Reliability: The strong construction of our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp ensures withstanding the imperative conditions of this manufacturing operations. This reliability ensures the infrastructure remains safe and functional, safeguarding the product and personnel.

Corrosion Resistance: Automotive manufacturing is exposed to humid environments and chemical exposure.

pH levels: Acidic 1-4 and Alkaline pH 9-12 aggravate corrosion.

Types of Corrosion: Uniform, Galvanic, Pitting, Crevice, Intergranular and Stress Corrosion Cracking (SCC).

Our UNICLAMP clamps are up for the challenge! Using environmental controls, corrosion-resistant coatings and paints, or cathodic protection on equipment, tools, and infrastructure is not required.

Conclusion

The automotive industry continually addresses risks and hazards to ensure a safe working environment. Technological advancements, regulatory changes, and shifting consumer preferences drive the constantly evolving automotive industry.

Utilization of our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp enhances productivity and safety, understanding that these aspects are not negotiable. Our UNICLAMP clamps proudly contribute.

For more information on Our Uniclamp products, please visit our website.