The primary purpose of nuclear power plants is to generate electricity.

The importance of safety in nuclear power plants cannot be overstated, given the potential consequences of accidents and the hazardous nature of radioactive materials.

Protection from radiation is the primary safety concern.

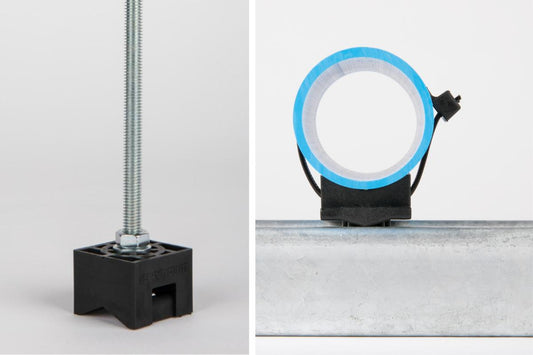

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are essential and pivotal assets fulfilling the primary safety concern of nuclear power plants. As Nuclear Power Plants processes cannot be interrupted, reliable and strong equipment are undebatable requirements in this industry. These processes command high levels of enhancement and credibility to ensure personnel safety and equipment integrity. Our UNICLAMP clamps attain all of these requirements.

Purposes and Benefits of The Nuclear Plant Industry

Minimal Greenhouse Gas Emissions: a cleaner energy source.

Base Load Power Supply: provide a steady and reliable source of electricity

Enhancing Energy Security: reduce dependence on fossil fuels.

Medical and Industrial Applications: by-products as certain isotopes

Uses and Advantages of Our Uniclamp Strut Pipe Clamp and V-BAT™ Pipe Clamp

Our UNICLAMP Pipe Clamps are applied when high mechanical strength, solidness, exceptional stability, pressure, and corrosive resistance are required.

Universal Fit and Compatibility

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are designed to accommodate numerous pipe sizes from 3/8" to 5" (9 mm up to 127 mm).

Our UNICLAMP Pipe Clamp’s design makes it compatible with an assortment of pipe and clamp materials: Low Alloy Steel, Carbon Steel, Stainless Steel, Inconel (Nickel-Chromium Alloys), Titanium, Copper-Nickel Alloys, and High-Density Polyethylene (HDPE) are used in Nuclear power Plants.

Piping Systems Used in The Nuclear Power Plant Industry

Main Pipelines:

Reactor Coolant Piping, Feedwater Piping, Steam Piping, Condensate Piping, Emergency Core Cooling System (ECCS) Piping, Auxiliary Piping, transporting the following products: water (heavy and de-mineralized), helium, steam, condensate, emergency coolant (water), process chemicals, waste products (radioactive and non-radioactive)

The selection of clamps for securing pipes in nuclear power plants is crucial to maintaining structural integrity and safety.

Commonly used clamps:

U-Bolts and Pipe clamps (Beam Clamps, Hose Clamps, Vibra-Clamp, Strut pipe Clamps, Spring Hangers, and Split Ring clamps)

These are some competitor clamps used to secure the six mentioned pipelines. Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp can replace all these clamps, with numerous benefits.

Our UNICLAMP Pipe Clamps are significantly more cost-effective than competitors.

The extreme conditions of the Nuclear Power Plants make our UNICLAMP Strut and V-BAT™ Pipe Clamps the ideal choice. This compatibility ensures that the same clamp can be used throughout all pipe installations, simplifying inventory management and procurement. Whether used for small or larger pipe installations, Our UNICLAMP Strut and Our V-BAT™ Pipe Clamps handle it all.

Durability and Non-Corrosiveness of Our Pipe Clamps

Both Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are manufactured from 30% glass-reinforced nylon 6.6, with tensile strengths of 900 lbs and 1100 lbs respectively, making them suitable for profound conditions (8700 - 12300 psi). Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are exceptionally robust, exhibiting outstanding mechanical strength and dependability. Our Pipe Clamps are resistant to rust, water, acid, alkaline, and corrosion. In addition, they provide wear and tear resistance and structural stability, making them indispensable for humid and corrosive environments. Saving money over time, this durability guarantees fewer replacements and lower maintenance costs.

UV Resistance

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp UV resistance guarantees a lifespan of 15-20 years, even in harsh environments, eliminating the need for UV-resistant coatings and materials to protect pipeline clamps.

Heavy-duty Strapping

Pipe installations implement heavy-duty strapping offering stability, strength, and endurance. Stainless steel strapping can support up to 200 lbs, varying thickness based on specific installations. Our nylon cable ties, made from UV-stabilized nylon 6.6, have a carrying capacity of up to 175 lbs. Our clamps and ties are specifically designed to ensure that pipes are securely held in place at all times, which is imperative for safe operation in Nuclear Power Plants

For more information on Strapping and Zip-tie options please check out our blog.

Chemical Exposure

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are acid and alkaline-resistant and 95% to most common chemicals guarantee no deterioration of our clamps when directly exposed to alkalines and acids. There are no visible signs of mechanical degradation or permanent chemical changes. Our UNICLAMP clamps are tremendously resistant to the 21 (twenty-one) chemicals with pH levels of less than 1 (Extreme acids) to 12 (Moderately strong bases) used in Nuclear power Plants.

Radiation exposure levels (absorbed dose):

Radiation exposure is measured in the International (SI) unit called the gray (Gy).

Limits are designed to minimize the risk of radiation-induced health effects while allowing workers to perform necessary tasks within nuclear facilities. Various regulatory bodies control the maximum radiation exposure limits for workers.

The maximum allowable annual exposure for nuclear plant workers:

International Commission on Radiological Protection (ICRP) and the European Union (EU) limits:

20 millisieverts (mSv) - equivalent to 0.02 grays (Gy) or 2 rads.

United States (Nuclear Regulatory Commission - NRC) limits:

50 millisieverts (mSv) - equivalent to 0.05 grays (Gy) or 5 rads

Actual exposure levels are usually much lower due to safety protocols.

Nylon 6.6 Radiation Tests:

Birkinshaw’s tests showed that high dose gamma radiation doses up to ~25 kGy = 25,000 Gy (2.5 Mrad = 2,500,000 rads) resulted in a ~5% loss in tensile modulus and yield stress of Nylon 6.6 (28)

(28) C. Birkinshaw, M. Buggy, and S. Daly, The Effect of Sterilising Radiation on the Properties of Nylon 66, Materials Chemistry and Physics, Vol 17, pp. 239-248, 1987.

Source: pp 9 SAND2013-8003P

Therefore, Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp have proven safe to be utilized even after radiation exposure.

Certifications

Our UNICLAMP Strut V-BAT™ Pipe Clamps are certified by UL2239, UL2043, ISO, RoHS, Reach, and Branz, providing confidence and assurance.

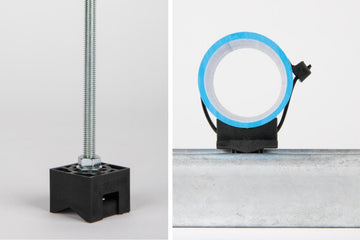

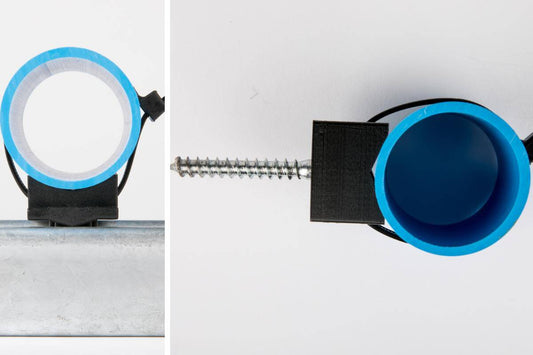

V-BAT™ Pipe Clamp

Our V-BAT Pipe Clamp is Compatible with Hilti tools for fast and effective concrete and surface installations, Our V-BAT™ Pipe Clamp's resilience is manifested by not displaying any fractures, shattering, or weakening, qualifying for heavy-duty applications. A socket wrench or ratchet is another option for easily installing Our V-BAT™ Pipe Clamp, advancing quick setups, and reducing labor expenses. The V-BAT™ Pipe Clamp offers versatile applications: flat surfaces, universal hangers, spacers, and Unistrut fixtures.

For more information on the numerous applications of Our V-BAT™ Pipe Clamps check out Our Blog.

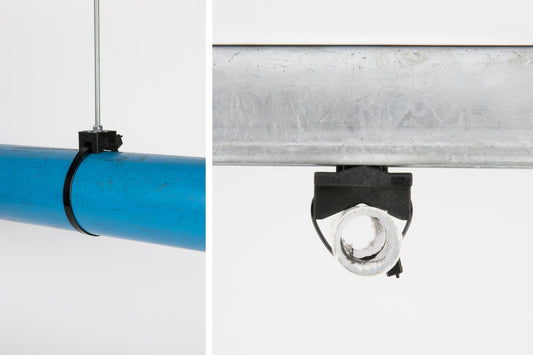

UNICLAMP Strut Pipe Clamp

Our UNICLAMP Strut Pipe Clamp cuts installation time by up to 83% compared to conventional clamps. Featuring a tool-free, simple place, twist, and strap interlocking system, a cost-effective option for all projects. This clamp can also be mounted as a hanger clamp on the Unistrut.

Temperature Resistance of Our UNICLAMP Strut and V-BAT™ Pipe Clamps

Minimum Service Temperature of -22°F to 266°F (-30°C to 130°C) and Maximum Service temperatures of 149°F - 550°F (65°C - 288°C) (MatWeb) authorize our UNICLAMP Strut and V-BAT™ Pipe Clamps to be used safely in Nuclear power plants, offering immense creep resistance.

For more information on Our Uniclamp Strut Pipe Clamp check out Our Blog.

Temperatures, Pressures, and Vibrations Generated by Nuclear Power Operations

Temperatures

Pressurized Water Reactor (PWR): coolant 599°F (315°C), steam 545°F (285°C).

Boiling Water Reactor (BWR): coolant 545°F (285°C).

Pressures

PWR: 2,250 psi (15.5 MPa)

BWR: 1,015 psi (7 MPa)

Vibrations

Pumps and Motors: 0.0393 in/s - 0.118 in/s (1-3 mm/s)(RMS)

Turbines: below 0.472 in/s (12 mm/s) (RMS)

Piping Systems: below 0.0393 in/s - 0.0787 in/s (1-2 mm/s) (RMS)

Reactor Coolant Pumps: below 0.1772 in/s (4.5 mm/s) (RMS)

Heat Exchangers and Condensers: below 0.0787 in/s - 0.118 in/s (2-3 mm/s) (RMS).

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp assimilate all pressures and vibrations without displaying any compressive mechanical stress eliminating the need for vibration reduction or rubber and elastomers lined equipment for vibration damping.

The UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp

Our UNICLAMP Strut and V-BAT™ pipe clamps are highly versatile products securing pipes, conduits, and tubing to various structures.

Nuclear power plants rely totally on piping systems to transport numerous critical products. Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp provide a tested and tried method of securing pipes, hoses, cables, and equipment to walls, ceilings, concrete floors, beams, and struts. Its vigorous construction guarantees that pipes remain unmoveable, averting leaks and maintaining the system's integrity.

The Uniclamp Strut and the V-BAT™ pipe clamps allow for trouble-free adjustments. This flexibility is crucial in the industry where changes in the process might require repositioning or adding new piping. The clamp’s design and functionality ensure these alterations are made without extensive downtime.

Safety and Efficiency

The safety and efficiency of Nuclear power plants are paramount. Both our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp contribute audaciously to these attributes in numerous ways:

Leak Prevention: By properly securing pipelines, the efficiency and safety of the Nuclear power process are secured, reducing the risk of leaks, breaks, and equipment failure. Leaks pose safety and health hazards. Exposure to ionizing radiation can occur due to leaks causing acute radiation sickness (ARS), long-term chronic health effects like cancer, and genetic mutations Leaks can also lead to widespread environmental contamination affecting wildlife, and agriculture. The potential for Hydrogen explosions, chemical reactions, or electrical fires is attributed to leaks. Wet and slippery floors create the possibility of slips and falls:

Ease of Maintenance: Installation of these clamps ensures that maintenance on pipes and equipment is performed rapidly and efficiently. This reduces downtime and ensures that Nuclear power operates smoothly. Note that all UNICLAMP pipe clamps are maintenance-free.

Strength and Reliability: The resilient construction of our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp guarantees to withstand the harsh conditions of the operations. This reliability pledges that the infrastructure remains functional and secure, safeguarding the product and personnel.

Corrosion Resistance: In nuclear power plants, it is a critical safety factor that affects the integrity and durability of various components, especially those involved in the reactor coolant system, steam generators, and other critical piping and equipment.

Types of Corrosion

General, Pitting, Intergranular, Galvanic, Flow-Accelerated (FAC) and Stress Corrosion Cracking (SCC)

Key aspects of the corrosion factor

Water Chemistry, Temperature, Pressure, Radiation, Mechanical Stresses, and pH imbalance.

None of these factors negatively impact our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp.

Conclusion

The primary safety concern is protecting human health and the environment, preventing accidents, complying with regulations, maintaining public confidence, and managing economic risks.

The comprehensive robust safety measures and regulatory oversight ensure that risks are effectively managed and limit the release of radiation.

Utilization of our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp enhances productivity and safety, understanding that these aspects are not negotiable. Our UNICLAMP clamps proudly contribute.

For more information on Our Uniclamp products, please visit our website.