The primary purpose of spacecraft production in the aerospace industry is to design, develop, and manufacture vehicles and systems capable of operating in outer space.

This encompasses a wide range of objectives, including:

Scientific Exploration: Space Probes and Rovers and Satellites

Communication: Satellites.

National Security and Defense: Reconnaissance Satellites

Navigation: Global Positioning System (GPS) Satellites

Human Spaceflight: Crewed Spacecraft and Space Habitats

Space Research and Development: Microgravity Experiments and Technology Demonstration

Commercial Activities: Space Tourism and Resource Utilization

Earth Observation and Environmental Monitoring: Remote Sensing Satellites

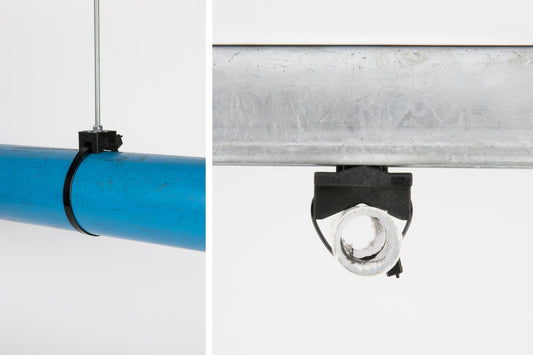

Spacecraft production commands extreme levels of efficiency and reliability to assure safety and equipment integrity. The infrastructure supporting this activity insists on robustness and versatility. Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are committed as their design meets the meticulous demands of spacecraft production in the aerospace industry.

Uses and Advantages of Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are applied when high mechanical strength, rigidity, good stability under heat or cold exposures, pressure, and corrosive resistance are required, eliminating galling.

Universal Fit

The UNICLAMP strut pipe clamp and the V-BAT™ pipe clamp are designed to accommodate a wide range of pipe sizes, from 3/8" to 5" (9 mm up to 127 mm).

Compatibility

Our clamp’s unique design makes it compatible with an assortment of pipe materials, including Aluminum Alloys, Titanium, Carbon Fiber Composites, Teflon (PTFE), Kevlar, Stainless steel, Ceramics, Inconel (Nickel-Based Alloys), Copper and Copper Alloys, PFA (Perfluoroalkoxy), Fiberglass and Silicon Carbide (SiC) Composites utilized in spacecraft production.

Main Pipelines in The Aerospace Industry

Pipes and piping systems transport different products essential for spacecraft production, ensuring safety and efficiency.

Cryogenic Lines, Hydraulic Systems, Fuel and Oxidizer Lines, Thermal Control Systems, Life Support Systems, and Fluid Transfer Lines.

Transporting the following products: liquid hydrogen, liquid oxygen, coolants, hydraulic fluids, fuel, and oxidizers. ammonia, glycol-water mixtures, air, remove carbon dioxide and manage humidity and temperature.

Selecting the Right Clamps

The selection of clamps for securing pipes in spacecraft production is crucial to maintaining structural integrity and safety. V-band clamps, T-Bolt Clamps, U-Bolt Clamps, Cushion Clamps (P-Clamps), Split Ring Clamps, Band Clamps, Hose Clamps, Quick-Release Clamps, Beam Clamps, and Spring Clamps are commonly used to secure various pipelines. However, our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp can replace all these competitors, offering superior strength, durability, and versatility.

Our UNICLAMP Pipe Clamps are significantly more cost-effective than assorted pipe-securing hardware types thus establishing our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp as the supreme fastener choice. This compatibility confirms that these clamps can be used throughout all pipe installations, streamlining inventory management and procurement. Whether used for small or larger pipes, the UNICLAMP strut and the V-BAT™ pipe clamps handle it all. This versatility reduces the need for multiple types of clamps, simplifying the installation process.

V-BAT™ Pipe Clamp

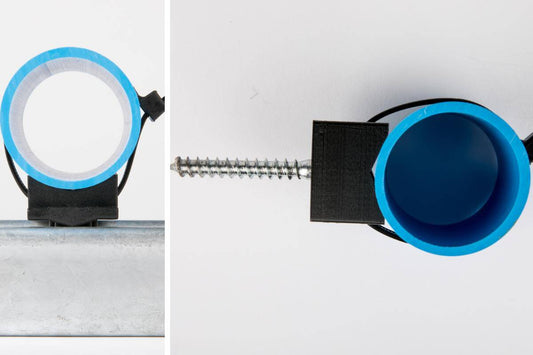

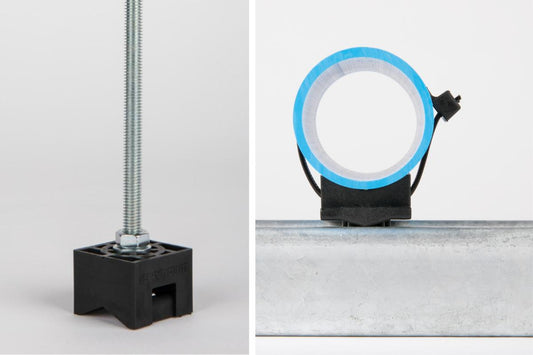

Time is money. Compatible with Hilti guns for quick and efficient installation in concrete, demonstrating the V-BAT™ Pipe Clamp's robustness, showing no signs of stress, cracks, shattering, or weakening, highlighting its suitability for heavy-duty use. Only a socket wrench or ratchet is required to ensure a user-friendly installation of the V-BAT™ pipe clamp, thus presenting an effortless way of rapid installation and cutting labor costs. The V-BAT™ Pipe Clamp is a four-way application: Flat surface, Universal hanger, Spacer, and Unistrut fixture.

UNICLAMP Strut Pipe Clamp

Speed of Installation

Our UNICLAMP Strut Pipe Clamp reduces installation time by up to 83% compared to traditional clamps. It is a tool-free uncomplicated place, twist, and strap interlocking system, making it an economical choice for all projects. This clamp can also be installed as a hanger clamp on the unistrut.

HDPE sleeve

Our HDPE sleeve is available to prevent insulation damage on pipes. Insulation is often used to mitigate temperature effects on pipes, especially in extreme climates.

High Durability of our Pipe Clamps

Both our UNICLAMP strut pipe clamp and the V-BAT™ pipe clamp are constructed from 30% glass-reinforced nylon 6.6, boasting a tensile strength of 900 lb and 1100 lbs respectively withstanding extreme conditions. (8700 - 12300 psi) These clamps are exceptionally rugged and display superior tensile and mechanical strength.

Non-Corrosiveness

Our Pipe Clamps are extremely resistant to rust, water, acid, alkalines, and corrosion, Additionally, they provide wear and tear imperviousness and structural stability, making them perfect for withstanding harsh and corrosive environments. The durability of our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp facilitate fewer replacements and lower maintenance costs, thereby saving additional expense.

Longevity

Our UNICLAMP clamps UV exposure durability ensures a long lifespan of 15-20 years, even in relentless environments, erasing the usage of UV-resistant coatings and materials to protect pipeline fasteners.

Heavy-duty Strapping Options

Heavy-duty strapping provides steadiness and strength to pipe installations. Stainless steel strapping can carry up to 200 lbs! (the thickness depends on your specific installation). Our nylon cable ties, made from nylon 6.6 are UV stabilized, and have a carrying capacity of up to 175lbs! Our clamps and ties are specifically designed to ensure that pipes are held firmly and securely in place at all times which is critical in spacecraft manufacturing.

For more information on Strapping and Zip-tie options please check out our blog.

Chemical exposure

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are acid and alkaline-resistant and 95% to most common chemicals guarantee no deterioration of our clamps when directly exposed. No visible signs of degradation or permanent chemical changes are detected. Our UNICLAMP clamps prove tremendously resistant to the 21 (Twenty-one) chemicals used in spacecraft production even when displaying highly acidic (pH 0-1) to highly basic (pH 13-14) levels.

Certifications

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are certified by UL2239, UL2043, ISO, RoHS, Reach, and Branz, providing confidence and assurance.

Temperature Resistance of our Our UNICLAMP Strut and V-BAT™ Pipe Clamps

Minimum Service Temperature of -22°F to 266°F (-30°C to 130°C) and Maximum Service temperatures of 149°F - 550°F (65°C - 288°C) (MatWeb) qualify Our UNICLAMP Strut and V-BAT™ Pipe Clamps to be safely used in spacecraft production, offering great resistance to creep.

For more information on Our Uniclamp Strut Pipe Clamp check out Our Blog.

Temperatures

During assembly: 68°F to 77°F (20-25°C)

In space: -454°F (-270°C) in the shadow of Earth to 248°F (120°C) in direct sunlight.

Cycle test:-11.2°F to 141.8°F ( -24°C to 61°C )

Source: (Table X page 128)

Pressures

Internal: Habitable environment 1 atm (101.3 kPa = 14.7 psi) for crewed missions.

External: In the vacuum of space, external pressure is virtually zero 10−4 Torr (7.5 millipascals (mPa) = 1.087783032975e-06 psi)

Source: (Table IX page 127)

Vibrations

Vibration levels can reach several g's (gravity forces), often exceeding 10 g (98 m/s²) = 321.5 ft/s² during launch.

The Flexural strength of our UNICLAMP clamps is 39000 psi, guaranteeing that our clamps are well within the flexural strength limits for the vibration and pressure levels.

Source

Standards and Guidelines

NASA-STD-7001: This standard outlines the requirements for dynamic testing, including vibration, shock, and acoustic testing.

MIL-STD-810: This U.S. military standard provides methods for environmental testing, including vibration and thermal tests.

MIL-HDBK-344 and MIL-STD-1540E: These handbooks provide guidelines for thermal testing, including thermal cycling and thermal vacuum tests.

Using Our Uniclamp Strut Pipe Clamp and V-BAT™ Pipe Clamp in Spacecraft Production

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are highly versatile assets securing pipes, conduits, and tubing to various structures.

Piping Systems Installation: Comprehensive crucial piping systems are required in spacecraft production. Our Uniclamp Strut and V-BAT™ Pipe Clamps provide a corroborated secured method to anchor pipes to walls, ceilings, struts, and floors. Attached to diverse materials including concrete, wood, and metal surfaces, our clamps ensure versatility and robustness in different installation environments. The vigorous construction of Our Uniclamp Strut and V-BAT™ Pipe Clamps guarantees that pipes stay securely in place, preventing leaks and preserving the system's integrity.

Easy Adjustments: Our UNICLAMP Strut and V-BAT™ pipe clamps allow for easy adjustments, required on demand. Adding flexibility in the spacecraft production setting where material or environmental changes might require repositioning or adding new piping. UNICLAMP’s design and functionality warrant these modifications are accomplished without extensive operational downtime.

Safety and Efficiency

The safety and productivity of spacecraft production are paramount. Both Our UNICLAMP Strut and V-BAT™ Pipe Clamp contribute significantly to both these aspects:

Leak Prevention: Utilizing our UNICLAMP Strut and V-BAT™ Pipe Clamps, securely installed pipes are less likely to leak, which is fundamental in maintaining the quality, consistency, and integrity of spacecraft production. Leaks pose safety hazards and result in wastage of valuable resources. Exposure to toxic and corrosive chemicals such as solvents, adhesives, cleaning agents, hydrochloric acid, sulfuric acid, nitric acid, and sodium hydroxide can cause severe burns and tissue damage upon contact. It can also lead to health issues ranging from skin irritation to respiratory problems and long-term health effects. Leaks of solvents and cleaning agents (e.g., acetone, isopropyl alcohol) are highly flammable and can pose fire and explosion risks. Certain chemicals may react violently with others, potentially causing explosions, fires, and toxic gas release confirming the requirement for stable pipelines.

Ease of Maintenance: Utilizing our UNICLAMP Strut and V-BAT™ Pipe Clamps validates that maintenance on pipes and equipment is accomplished quickly and efficiently. This reduces downtime and ensures that the power plant process operates uninterrupted. Note that all UNICLAMP pipe clamps are maintenance-free.

Strength and Reliability: The robust construction of Our UNICLAMP Strut and V-BAT™ Pipe Clamps withstand harsh conditions. Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp validate that the infrastructure remains safe and functional, protecting the product and personnel.

Corrosion Resistance: Pipes in spacecraft production are manufactured to withstand harsh environments and chemical exposure. Water, steam, oxygen, and chemical contact accelerate galvanic corrosion and rust formation. Our UNICLAMP clamps are completely non-corrosive, there is no need for cathodic protection or protective coatings or linings like epoxy, polyurethane, or zinc to create a barrier against corrosive elements.

Radiation hazards in spacecraft production primarily involve ionizing radiation from X-ray and gamma-ray testing and non-ionizing radiation from UV, IR, microwaves, and lasers. By adhering to regulatory limits and implementing robust safety measures, these hazards are effectively managed to protect workers' health and safety.

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp have proven safe to be utilized even after excessive radiation exposure.

Summary

In essence, spacecraft production is integral to advancing our capabilities in space exploration, enhancing communication and navigation on Earth, ensuring national security, enabling scientific discoveries, and opening new commercial opportunities. Spacecraft production generates vibrations from testing and flow dynamics, including mechanical equipment, necessitating robust fasteners. Our UNICLAMP Strut pipe clamp and the V-BAT™ Pipe Clamp ensure long-term durability and guarantee safe and secure pipe installations and operational efficiency that you can rely upon for years.

For more information on these products, you can visit our official pages.