The primary purpose of geothermal power plants is to generate electricity in an environmentally friendly manner by utilizing the natural heat from the Earth's interior.

This process commands high optimization, dependability, versatility, and reliability to ensure personnel safety and equipment integrity. Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are crucial assets designed to meet the rigorous diverse demands of Geothermal power plants.

Uses and Advantages of Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp

Our UNICLAMP Pipe Clamps are utilized where high mechanical strength, rigidity, good stability under heat or cold exposures, pressure, and corrosive resistance are required.

Universal Fit

Our UNICLAMP strut pipe clamp and V-BAT™ pipe clamp are designed to facilitate a comprehensive range of pipe sizes, from 3/8" to 5" (9 mm to 127 mm).

Compatibility

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp design make it compatible with numerous pipe materials. Carbon steel, Stainless steel, High-Alloy Materials, and Reinforced concrete pipes are used in Geothermal power plants. The materials chosen for these pipelines are critical to ensure durability and resistance to the harsh geothermal environment. Our UNICLAMP Strut and V-BAT™ Pipe Clamps qualify as the ideal fastener choice. This compatibility guarantees that the same clamp can be used throughout pipe installations, simplifying procurement and inventory management. Whether used for small or larger pipes, our UNICLAMP Strut and Our V-BAT™ Pipe Clamps can facilitate it all.

Durability of our Pipe Clamps

Both our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are manufactured from 30% glass-reinforced nylon 6.6, with tensile strengths of 900 lbs and 1100 lbs respectively, making them suitable for extreme conditions (8700 - 12300 psi). Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are exceptionally durable, demonstrating excellent tensile and mechanical strength and robustness.

Non-Corrosiveness

Our Pipe Clamps are extremely resistant to rust, water, acid, alkalines, and corrosion, Additionally, they provide wear and tear imperviousness and structural stability, making them perfect for humid and corrosive environments. Water and steam being highly abrasive, accelerate potential pipeline and fastener failure. The durability of our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp facilitate fewer replacements and lower maintenance costs, thereby saving money.

UV Resistance

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp UV resistance guarantees a lifespan of 15-20 years, even in brutal environments, abolishing the need for UV-resistant coatings and materials to protect pipeline fasteners.

Heavy-duty Strappings options

Heavy-duty strapping offers solidity and vigorousness for pipe installations. Stainless steel strapping can support up to 200 lbs and specific installations determine the thickness of the strap Our nylon cable ties, made from UV-stabilized nylon 6.6, have a carrying capacity of up to 175 lbs. The specific design of our clamps and ties ensures that pipes are securely held in place at all times, which is crucial for Geothermal power plants.

For more information on Strapping and Zip-tie options please check out our blog.

Chemical Exposure

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are acid and alkaline-resistant and 95% to most common chemicals guarantee no deterioration of our clamps when directly exposed. No visible signs of degradation or permanent chemical changes are detected. Our UNICLAMP clamps prove tremendously resistant to the 31 (Thirty-one) chemicals used in the geothermal industry displaying pH levels between 2-3 Acidic Fluids to 8-9 Alkaline Fluids.

Certifications

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are certified by UL2239, UL2043, ISO, RoHS, Reach, and Branz, providing confidence and assurance.

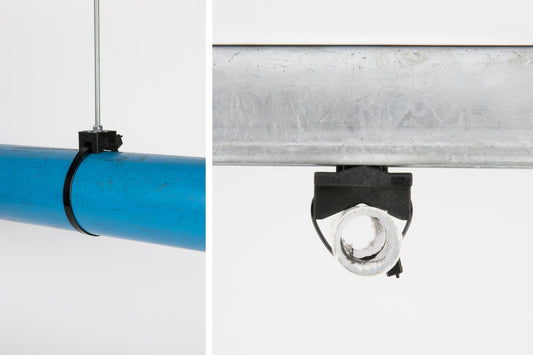

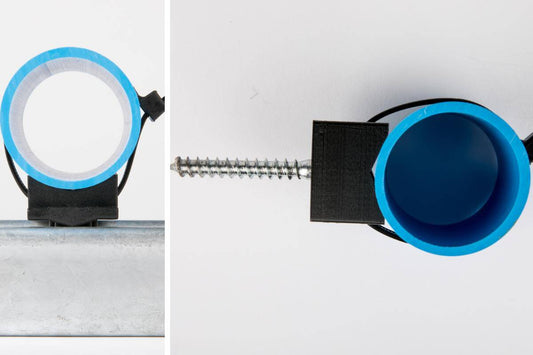

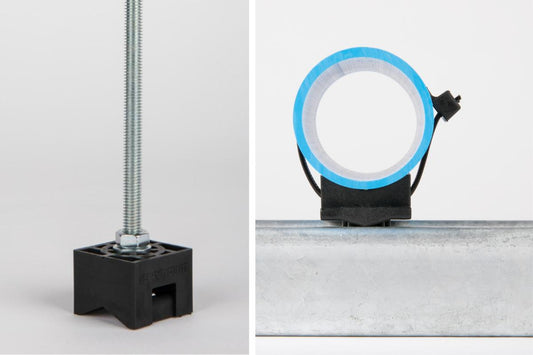

V-BAT™ Pipe Clamp

Time is valuable. Compatible with Hilti tools for fast and effective concrete and surface installations, Our V-BAT™ Pipe Clamp's durability is proven by not displaying any fractures, shattering, or weakening, exhibiting its capability for heavy-duty applications. A socket wrench or ratchet is another option for simply installing Our V-BAT™ Pipe Clamp, facilitating quick setups and reducing labor expenses. The V-BAT™ Pipe Clamp offers versatile applications: flat surfaces, universal hangers, spacers, and Unistrut fixtures.

For more information on the numerous applications of Our V-BAT™ Pipe Clamps check out Our Blog.

UNICLAMP Strut Pipe Clamp

Our UNICLAMP Strut Pipe Clamp cuts installation time by up to 83% compared to traditional clamps. Featuring an uncomplicated tool-free, simple place, twist, and strap interlocking system, a cost-effective option for all projects. This clamp can also be mounted as a hanger clamp on the Unistrut.

HDPE Sleeve

Our HDPE Sleeve is designed to prevent damage to pipe insulation. HDPE Sleeve Insulation is employed to prevent cross-contamination and reduce temperature impacts on pipelines, particularly in extreme climates.

For more information on Our HDPE Sleeve check out Our Blog called Enhancing HVAC System Performance with V-BAT Pipe Clamps and HDPE Sleeves.

Temperature Resistance of Our UNICLAMP Strut and V-BAT™ Pipe Clamps

Minimum Service Temperature of -22°F to 266°F (-30°C to 130°C) and Maximum Service temperatures of 149°F - 550°F (65°C - 288°C) (MatWeb) qualify Our UNICLAMP Strut and V-BAT™ Pipe Clamps to be safely used in the raw gas transportation environment, offering great resistance to creep.

For more information on Our Uniclamp Strut Pipe Clamp check out Our Blog.

Temperatures, Pressure, and Vibrations Generated by Geothermal Power Plant Operations:

Temperatures

High-Temperature Reservoirs: 302°F to 698°F (150°C to 370°C)

Medium-Temperature Reservoirs: 194°F to 302°F (90°C to 150°C).

Low-Temperature Reservoirs: Below 194°F (90°C).

Dry Steam Plants: 302°F(150°C).

Flash Steam Plants: 356°F and 698°F (180°C and 370°C).

Binary Cycle Plants: 185°F to 356°F (85°C to 180°C)

Pressures

Geothermal Reservoirs: 29 to 580 psi (2 to 40 bar) depending on the depth and temperature of the reservoir.

Power Plant Operations:

Dry Steam Plants: 116 to 145 psi (8 to 10 bar).

Flash Steam Plants: 145 to 290 psi (10 to 20 bar)

Binary Cycle Plants: 73 to 218 psi (5 to 15 bar)

Vibration Values

Drilling Operations: Up to 0.4-2 inches/second (10-50 mm/s) or higher, depending on the drilling rig and rock hardness.

Pumps and Motors: below 0.18 inches/second (4.5 mm/s) for pumps and motors according to ISO 10816 standards for new equipment.

Turbines and Generators: below 0.11 inches/second (2.8 mm/s), alarms set at 0.18 inches/second (4.5 mm/s).

Piping and Valves: below 0.28 inches/second (7.1 mm/s) to avoid fatigue and potential failure of the piping system.

Our UNICLAMP Strut and V-BAT™ Pipe Clamps absorb all pressures and vibrations not showing any compressive stress.

Using Our Uniclamp Strut Pipe Clamp and V-BAT™ Pipe Clamp in Geothermal Power Plants

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are highly versatile assets securing pipes, conduits, and tubing to various structures.

Piping Systems Installation: Comprehensive piping systems are required in the Geothermal Power Plants. Our Uniclamp Strut and V-BAT™ Pipe Clamps provide a corroborated secured method to secure pipes to walls, ceilings, struts, and floors. Attached to various materials including concrete, wood, and metal surfaces, our clamps ensure versatility and robustness in different installation environments. The robust construction of Our Uniclamp Strut and V-BAT™ Pipe Clamps ensures that pipes stay securely in place, preventing leaks and preserving the system's integrity.

Easy Adjustments: Our UNICLAMP Strut and V-BAT™ pipe clamps allow for easy adjustments, required on demand. Adding flexibility in the power plant setting where material or environmental changes might require repositioning or adding new piping. UNICLAMP’s design and functionality warrant these modifications are accomplished without extensive operational downtime.

Safety and Efficiency

The safety and productivity of the Geothermal Power Plants are paramount. Both Our UNICLAMP Strut and V-BAT™ Pipe Clamp contribute significantly to both these aspects:

Leak Prevention: Securely installed pipes utilizing our UNICLAMP Strut and V-BAT™ Pipe Clamps are less likely to leak, which is fundamental in maintaining the quality, consistency, and integrity of Geothermal Power Plants. Leaks pose safety hazards and result in wastage of valuable resources. Inhalation of toxic gases like hydrogen sulfide (H₂S) can be fatal, and exposure to chemicals causes long-term health issues. Spills also pose environmental risks Flammable gas (methane and hydrogen sulfide) leaks pose explosion and fire risks.

Ease of Maintenance: Utilizing our UNICLAMP Strut and V-BAT™ Pipe Clamps validates that maintenance on pipes and equipment is accomplished quickly and efficiently. This reduces downtime and ensures that the power plant process operates uninterrupted. Note that all UNICLAMP pipe clamps do not require maintenance.

Strength and Reliability: The robust construction of Our UNICLAMP Strut and V-BAT™ Pipe Clamps can withstand harsh conditions. High winds, rain, snow, ice, and immense heat impose additional mechanical stress on pipelines and fasteners. Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp's reliability validates that the infrastructure remains safe and functional, protecting the product and the personnel.

Corrosion Resistance: Pipes in geothermal power plants are manufactured to withstand harsh and humid environments and chemical exposure. Water, steam, oxygen, and pollutants exposure accelerates galvanic corrosion and rust formation. Our UNICLAMP clamps are completely non-corrosive, there is no need for cathodic protection or protective coatings or linings like epoxy, polyurethane, or zinc to create a barrier against corrosive elements.

Cost-effectiveness of our UNICLAMP and V-BAT Pipe Clamp

Our UNICLAMP Strut and V-BAT™ Pipe Clamps are significantly more cost-effective compared to various types of pipe securing hardware.

U-Bolts: For instance, a stainless steel U-bolt from Ferguson costs approximately $61.89 for a 4-inch size, and up to $252.04 for larger sizes (Ferguson) (Empire Industries). Other suppliers offer U-bolts in the range of $46.65 to $158.69 based on the specifications and material quality (Piping Technology & Products, Inc.).

Pipe Hangers: These are available at various price points, with some galvanized pipe hangers costing around $5 each depending on the size and complexity (The Home Depot).

In comparison, Our UNICLAMP Strut and V-BAT™ Pipe Clamps are priced at $2.49 each, or $2.20 when bought in bulk. This makes Our Uniclamps substantially cheaper, offering savings of up to 98.15% compared to some stainless steel split clamps and 77% compared to standard galvanized pipe clamps (Uniclamp USA) (Uniclamp USA).

To Purchase Our Uniclamp Products click here.

Conclusion

Geothermal Power Plants generate vibrations from drilling and external mechanical equipment, necessitating robust fasteners. Atmospheric influences such as corrosion, temperature extremes, UV radiation, wind, weather, and seismic activity radically affect pipeline integrity. Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp guarantee continuing endurance and strength affirming intact and secure pipe installations and operational efficiency that can be dependent upon for years.

For more information on Our Uniclamp products, please visit our website.