Coal is a vital natural resource used for various purposes: Energy Production, Steel Production, Industrial Processes, and as a Heating fuel. The infrastructure supporting underground coal mining activities must be robust and versatile. Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp play an imperative role as these products are designed to meet the rigorous demands of underground coal mining.

Uses and Advantages of Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are applied when high mechanical strength, robustness, good stability under heat or cold exposures, pressure, and corrosive resistance are required, eliminating galling.

Universal Fit

Our UNICLAMP Strut Pipe Clamp and V-BAT™ pipe clamp are designed to accommodate a wide range of pipe sizes, from 3/8" to 5" (9 mm up to 127 mm).

Compatibility

Our UNICLAMP Strut Pipe Clamp and V-BAT Pipe Clamps unique design makes it compatible with an assortment of pipe materials, including Steel, HDPE, Rubber-lined Steel, Flexible PVC, Copper, Fiberglass-reinforced Plastic (FRP), Vinyl-coated Fabric, Galvanized Steel, Aluminum, Rubber-lined Steel used in underground coal mining.

Ease of Installation

The ability to secure pipes quickly with minimal tools is a significant and crucial advantage in Underground Coal Mining.

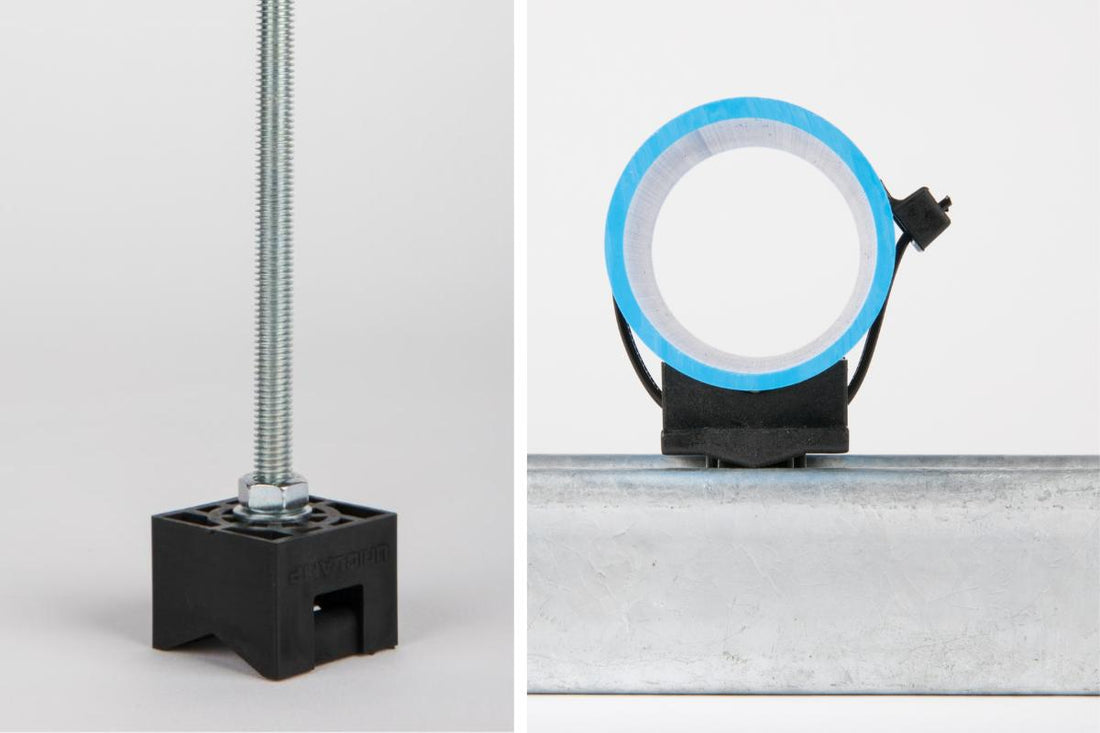

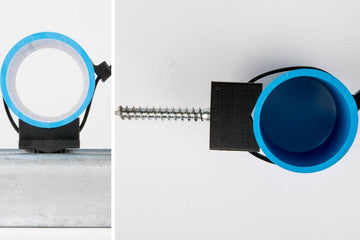

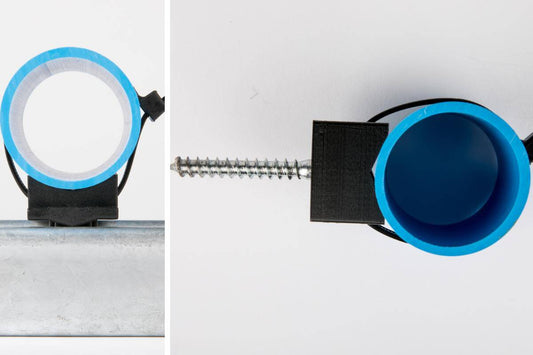

V-BAT™ Pipe Clamp

Our V-BAT™ Pipe Clamp is Compatible with Hilti guns for quick and efficient installation in concrete, demonstrating the V-BAT™ Pipe Clamp's robustness, showing no signs of stress, cracks, shattering, or weakening, highlighting its suitability for heavy-duty use. Only a socket wrench or ratchet is required to ensure a user-friendly installation of the V-BAT™ pipe clamp, thus presenting an effortless way of rapid installation and cutting labor costs. The V-BAT™ Pipe Clamp is a four-way application: Flat surface, Universal hanger, Spacer, and Unistrut fixture.

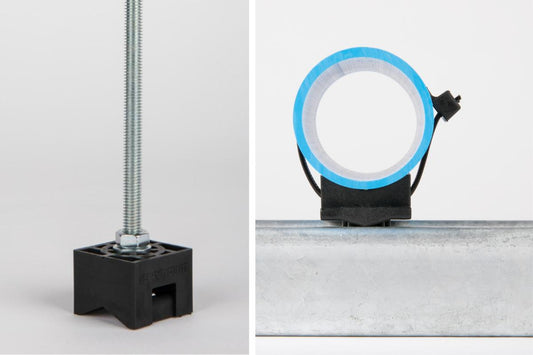

UNICLAMP Strut Pipe Clamp

Speed of Installation

Our UNICLAMP Strut Pipe Clamp reduces installation time by up to 83% compared to traditional clamps. It is a tool-free uncomplicated place, twist, and strap interlocking system, making it an economical choice for all projects. This clamp can also be installed as a hanger clamp on the unistrut.

For more information on Our Uniclamp Strut Pipe Clamp check out Our Blog.

HDPE Sleeve

Our HDPE sleeve is available to prevent insulation damage on pipes. Insulation is often used to mitigate temperature effects on pipes, especially in extreme climates such as Underground Mines.

For more information on Our HDPE Sleeve check out Our Blog called Enhancing HVAC System Performance with V-BAT Pipe Clamps and HDPE Sleeves.

High Durability of Our Pipe Clamps

Both our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are constructed from 30% glass-reinforced nylon 6.6, boasting a tensile strength of 900 lb and 1100 lbs respectively withstanding extreme conditions (8700 - 12300 psi). These clamps are extremely solid and display superior tensile and mechanical strength.

Non-Corrosiveness

Our Pipe Clamps are extremely resistant to rust, water, acid, alkalines, and corrosion, Additionally, they provide unyielding wear and tear and structural stability, making them ideal to withstand brutal and corrosive environments. The resilience of our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp guarantees fewer replacements and lower maintenance costs, thereby saving additional expenses.

Longevity

Our UNICLAMP and V-BAT Pipe Clamps have a 15-20 year UV lifespan, even in harsh environments, eliminating the usage of UV-resistant coatings and materials to safeguard pipelines and clamps.

Pipe Installation Strapping

Heavy-duty strapping ensures steadiness and strength to pipe installations. Stainless steel strapping can carry up to 200 lbs! (the thickness depends on your specific installation). Our nylon cable ties, made from 6.6, are UV stabilized and have a carrying capacity of up to 175lbs! Our clamps and ties are designed to ensure that pipes are held firmly and securely in place at all times which is critical in Underground Mining.

For more information on Strapping and Zip-tie options please check out our blog.

Chemical Exposure

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are acid and alkaline-resistant and 95% to most common chemicals guarantee no deterioration of our clamps when directly exposed. No visible signs of degradation or permanent chemical changes are detected. Our UNICLAMP clamps prove tremendously resistant to the 18 (Eighteen) chemicals used in Underground Coal Mining even when directly exposed to Lime (Calcium Hydroxide) with pH levels of 10-12 and Sulfuric Acid with pH levels of 1-2.

Certifications

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are certified by UL2239, UL2043, ISO, RoHS, Reach, and Branz, providing confidence and assurance.

Temperature, Pressure, and Vibrations Resistance of Our UNICLAMP Strut and V-BAT™ Pipe Clamps

Minimum Service Temperature of -22°F to 266°F (-30°C to 130°C) and Maximum Service temperatures of 149°F - 550°F (65°C - 288°C) (MatWeb) qualify Our UNICLAMP Strut and V-BAT™ Pipe Clamps to be safely utilized in Underground Coal Mining, providing excellent resistance to creep.

For more information on Our Uniclamp Strut Pipe Clamp check out Our Blog.

Temperatures

Ambient Temperatures

Shallow Mines: 50°F to 68°F (10°C to 20°C).

Deep Mines: 86°F (30°C ) up to 122°F (50°C).

Heat Generated by Equipment: adds 9°F to 27°F (5°C to 15°C) to ambient temperature.

Cooling Systems maintain temperatures around 68°F to 82°F (20°C to 28°C).

Heat Management: To ensure miner safety, regulations require that temperatures do not exceed 82.4°F to 86°F (28°C to 30°C).

Vibrations

Blasting Vibrations: 0.003937 in/s to 11.811 in/s (0.1 mm/s to 300 mm/s) peak particle velocity (PPV).

Controlled blasting below 1.9685 in/s (50 mm/s) PPV to avoid structural damage.

Machinery-induced vibrations from 0.003937 in/s to 0.3937 in/s (0.1 mm/s to 10 mm/s) PPV.

Seismic Events (microseisms) can have magnitudes from less than 1.0 to around 3.0 on the Richter scale.

Pressures

Rock Pressure

Overburden Pressure: at 1000 meters, the pressure is 3915.92 psi (27 MPa) (megapascals).

Air Pressure

Ventilation Pressure: from 0.0725 psi to 1.45 psi (0.5 kPa to 10 kPa (kilopascals)

Methane Control: levels at 1% to 2% by volume in the air.

Hydraulic Pressure

Hydraulic Supports: from 1450.38 psi to 7251.89 psi (10 MPa to 50 MPa).

It is proven that the levels and limits of temperatures, vibrations, and pressures in Underground Coal Mining are absorbed by our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp providing peace of mind.

Using Our Uniclamp Strut Pipe Clamp and V-BAT™ Pipe Clamp in Underground Coal Mining

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are highly versatile assets securing pipes, conduits, and tubing to various structures.

Main Pipelines of Underground Mining

In Underground Coal Mining, pipelines are essential for various functions, including water management, ventilation, slurry transport, and the conveyance of compressed air and gases.

Water Pipelines, Slurry Pipelines, Compressed Air Pipelines, Ventilation Ducts and Pipelines, Gas Pipelines, Fire Suppression Pipelines, Backfill Pipelines,

Transporting the following products: water (firefighting and process water), coal slurry, compressed and fresh air to remove hazardous gases (methane) and dust, sand, cement, and waste rock.

Piping Systems Installation

Comprehensive crucial piping systems are required in Underground Coal Mining. Our Uniclamp Strut and V-BAT™ Pipe Clamps provide a tested reinforced method to anchor pipes to walls, ceilings, struts, floors, and rockfaces. Attached to diverse materials including concrete, wood, metal surfaces, and rock, our clamps ensure versatility and strength in various installations. The dynamic construction of Our Uniclamp Strut and V-BAT™ Pipe Clamps pledges that pipes are securely bound in place, preventing leaks, preserving the system's integrity, and enhancing safety.

Easy Adjustment of Our Uniclamp and V-BAT Pipe Clamps

Our UNICLAMP Strut and V-BAT™ pipe clamps allow for easy adjustments, required on demand, adding flexibility in Underground Coal Mining where operational or environmental changes could require repositioning or adding new piping. UNICLAMP’s design and functionality warrant these modifications are accomplished without extensive operational downtime.

Safety and Efficiency

The safety and productivity of mining operations are preeminent. Both Our UNICLAMP Strut and V-BAT™ Pipe Clamp contribute boldly to both requirements.

Leak Prevention: Utilizing Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp, securely installed pipes are less likely to leak, which is fundamental in maintaining the quality, consistency, and integrity of Underground Coal Mining. A pipeline leak can provide an ignition source for methane, leading to explosions. If a pipeline carries flammable fluids a leak can result in fires or explosions. Leaks can release carbon monoxide, a colorless, odorless, and toxic gas, which can be fatal at high concentrations, and also hydrogen sulfide, which is toxic and causes respiratory issues and other health problems. A leak in water pipelines can result in flooding, which can trap miners, damage equipment, and hinder evacuation efforts. Prolonged leaks can erode the ground around the pipeline, potentially compromising the structural integrity of the mine, and leading to collapses or cave-ins.

Leaks can force a halt in mining operations, leading to financial losses and impacting supply chains.

Ease of Maintenance: Utilizing Our UNICLAMP Strut and V-BAT™ Pipe Clamps validates that maintenance on pipes and equipment is accomplished quickly and efficiently. This reduces downtime and ensures that Underground Coal Mines operate uninterrupted. Note that all UNICLAMP pipe clamps are maintenance-free.

Strength and Reliability: The robust construction of Our UNICLAMP Strut and V-BAT™ Pipe Clamps withstand brutal conditions. Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp guarantee that the infrastructure remains safe and functional, protecting the product and mine personnel.

Corrosion Resistance: Pipes in Underground Coal Mines are manufactured to sustain inhospitable environments and chemical exposure. High humidity and water ingress, acid mine water, salts and chlorides, coal dust, and chemical reactions between metal surfaces and mine gases like carbon dioxide, hydrogen sulfide, and methane can accelerate galvanic corrosion and rust formation resulting in pitting. Our UNICLAMP clamps are completely non-corrosive, there is no need for cathodic protection or protective coatings or linings like epoxy, polyurethane, or zinc to create a barrier against corrosive elements.

Radiation Exposure Hazards in Underground Coal Mines

Real-World Examples:

U.S. Mines: Studies in some U.S. coal mines have found radon levels typically ranging from 200 Bq/m³ (13.14 mSv/year = 0.01314 Gy/year = 1.314 rad/year) to 1000 Bq/m³ (65.7 mSv/year = 0.0657 Gy/year = 6.57 rad/year).

European Mines: Radon Concentrations have been reported to range from 100 Bq/m³ (6.57 mSv/year = 0.00657 Gy/year = 0.657 rad/year) to 500 Bq/m³ (32.85 mSv/year = 0.03285 Gy/year = 3.285 rad/year). Levels can exceed 1000 Bq/m³ (65.7 mSv/year, 0.0657 Gy/year, 6.57 rad/year).

Australian Mines have reported radon levels below 500 Bq/m³ (32.85 mSv/year = 0.03285 Gy/year = 3.285 rad/year), with some reaching up to 1500 Bq/m³ (98.55 mSv/year = 0.09855 Gy/year = 9.855 rad/year).

The International Commission on Radiological Protection (ICRP) recommends that radon exposure should not exceed an annual dose of 10 mSv (millisieverts) for occupational exposure, which corresponds to approximately 500 to 1000 Bq/m³.

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp have proven safe to be utilized even after excessive radiation exposure.

Source: pp 9 SAND2013-8003P

Conclusion

Safety in Underground Coal Mining is essential to protect miners' lives, ensure regulatory compliance, maintain operational efficiency, protect the environment, and foster positive community relations. Continuous investment in safety measures, training, and technology is crucial to mitigating the inherent risks associated with underground coal mining.

Utilization of our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp enhances productivity and safety, understanding that these aspects are not negotiable.

For more information on Our Uniclamp products, please visit our website.