The primary purpose of Offshore Drilling is to extract hydrocarbon (oil and natural gas) from reservoirs beneath the ocean floor. By proactively identifying and managing hazards, offshore drilling operations risks are significantly reduced ensuring the safety of personnel, the maintenance of the environment, and equipment.

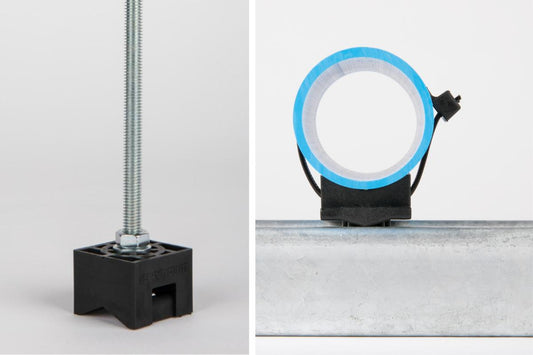

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are crucial and Indispensable assets designed to meet the rigorous specialized demands of offshore drilling as the infrastructure supporting this activity insists on resiliency and versatility. This process commands high levels of efficiency and reliability to ensure safety and equipment integrity. Our UNICLAMP clamps fulfill all of these requirements.

Key Purposes and Benefits of Offshore Drilling

1. Access to Large Reserves

Extended Reach and Significant Production

2. Energy Supply

Meeting Demand and Global Energy Security

3. Economic Benefits

Job Creation and Government Revenue Generation

4. Technological Advancements

Innovation and Engineering Expertise

5. Strategic Reserves

National Reserves and National Economic Stability

6. Environmental Considerations

Reduced Land Impact and Controlled Operations

Uses and Advantages of Our Uniclamp Strut Pipe Clamp and V-BAT™ Pipe Clamp

Universal Fit and Compatibility

Our UNICLAMP strut pipe clamp and V-BAT™ pipe clamp are designed to accommodate a wide range of pipe sizes, from 3/8" to 5" (9 mm up to 127 mm)

Our UNICLAMP Pipe Clamp’s design makes it compatible with an assortment of pipe and fastener materials: Alloy Steel, Carbon Steel, Stainless Steel, Inconel, Monel, Titanium, Duplex, and Super Duplex Stainless Steel Alloy Steel) used in the offshore drilling environment. The specific extreme conditions of the drilling environment make Our UNICLAMP Strut and V-BAT™ Pipe Clamps the ideal fastener choice. This compatibility ensures that the same clamp can be used throughout pipe installations, simplifying inventory management and procurement. Whether used for small or larger pipe installations, Our UNICLAMP Strut and Our V-BAT™ Pipe Clamps will handle it all.

Durability and Non-Corrosiveness of Our Pipe Clamps

Both Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are manufactured from 30% glass-reinforced nylon 6.6, with tensile strengths of 900 lbs and 1100 lbs respectively, making them suitable for profound conditions (8700 - 12300 psi). Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are highly durable, demonstrating superior tensile strength and reliability. Our Pipe Clamps are resistant to rust, water, acid, and corrosion. Additionally, they provide wear resistance and dimensional stability, making them ideal for humid and corrosive environments commonly faced by offshore drilling. This durability leads to fewer replacements and lower maintenance costs, saving money over time. Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp UV resistance guarantees a lifespan of 15-20 years, even in harsh environments, eliminating the need for UV-resistant coatings and materials to protect pipeline fasteners.

Pipe installations implement heavy-duty strapping offering stability, strength, and endurance. Stainless steel strapping can support up to 200 lbs, with thickness varying based on specific installations. Our nylon cable ties, made from UV-stabilized nylon 6.6, have a carrying capacity of up to 175 lbs. Our clamps and ties are specifically designed to ensure that pipes are securely held in place at all times, which is vital in onshore drilling.

For more information on Strapping and Zip-tie options please check out our blog.

Chemical Exposure

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are acid resistant and 95% to most common chemicals guarantee no deterioration of our clamps when directly exposed to alkalines and acids. There are no visible signs of degradation or permanent chemical changes. Our UNICLAMP clamps are tremendously resistant to Hydrocarbons.

Certifications

Our UNICLAMP Strut V-BAT™ Pipe Clamps are certified by UL2239, UL2043, ISO, RoHS, Reach, and Branz, providing confidence and assurance.

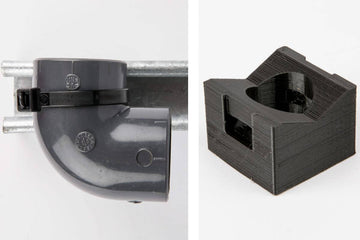

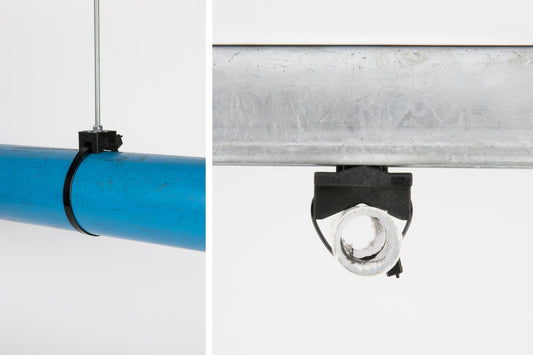

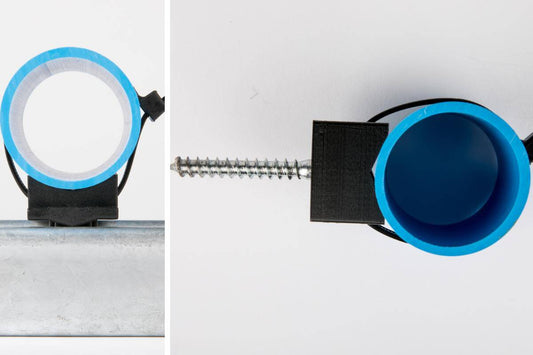

V-BAT™ Pipe Clamp

Time is valuable. Compatible with Hilti tools for fast and effective concrete and surface installations, Our V-BAT™ Pipe Clamp's robustness is evident by not displaying any fractures, shattering, or weakening, proving its capacity for heavy-duty applications. A socket wrench or ratchet is another option for simply installing Our V-BAT™ Pipe Clamp, facilitating quick setups and reducing labor expenses. The V-BAT™ Pipe Clamp offers versatile applications: flat surfaces, universal hangers, spacers, and Unistrut fixtures.

For more information on the numerous applications of Our V-BAT™ Pipe Clamps check out Our Blog.

UNICLAMP Strut Pipe Clamp

Our UNICLAMP Strut Pipe Clamp cuts installation time by up to 83% compared to conventional clamps. Featuring a tool-free, simple place, twist, and strap interlocking system, a cost-effective option for all projects. This clamp can also be mounted as a hanger clamp on the Unistrut.

Our HDPE Sleeve is designed to prevent damage to pipe insulation. HDPE Sleeve Insulation is often employed to avoid cross-contamination and reduce temperature impacts on transport pipes, particularly in extreme climates.

For more information on Our HDPE Sleeve check out Our Blog called Enhancing HVAC System Performance with V-BAT Pipe Clamps and HDPE Sleeves.

Temperature Resistance of our Our UNICLAMP Strut and V-BAT™ Pipe Clamps

Minimum Service Temperature of -22°F to 266°F (-30°C to 130°C) and Maximum Service temperatures of 149°F - 550°F (65°C - 288°C) (MatWeb) qualify Our UNICLAMP Strut and V-BAT™ Pipe Clamps to be safely used in the offshore drilling environment, offering great resistance to creep.

For more information on Our Uniclamp Strut Pipe Clamp check out Our Blog.

Temperatures, Pressures, and Vibrations Generated by Offshore Drilling

Temperatures

Surface and Ambient Temperatures

In tropical regions, temperatures can exceed 30°C (86°F), and in the polar areas, temperatures can drop below -20°C (-4°F). These conditions require rigs and equipment, like our UNICLAMP Strut and V-BAT™ Pipe Clamp, to resist extreme heat and cold.

Seawater Temperatures

Thermocline Effect: The surface layer (epipelagic zone) may be warm, but deeper layers (mesopelagic and bathypelagic zones) are much colder.

Deepwater Temperatures: At depths beyond 3,280 feet (1,000 meters), seawater temperatures typically range from 35.6°F to 39.2°F (2°C to 4°C).

Downhole Temperatures

Geothermal Gradient: The geothermal gradient is approximately 72-87°F per mile (25-30°C per kilometer).

Extreme Downhole Temperatures: Temperatures can reach 302°F to 392°F (150°C to 200°C) or higher.

Pressure

Hydrostatic Pressure

At a depth of 3,280 feet (1,000 meters), the hydrostatic pressure is approximately 1,450 psi (10 MPa).

Formation Pressure

Core pressure varies greatly depending on the geological conditions.

In deepwater and ultra-deepwater drilling, hydrocarbon reservoir pressures can exceed 14,500 psi (100 MPa).

Vibrations

Drilling operations generate axial, torsional, and lateral vibrations, which impact drilling efficiency and equipment integrity.

Our UNICLAMP Strut and V-BAT™ Pipe Clamps absorb all pressures and vibrations not showing any compressive stress.

Corrosion

Corrosion is a significant and consequential factor in offshore drilling due to harsh marine environments, compromising the structural integrity of offshore platforms, pipelines, and other critical infrastructure, posing major safety risks.

Key aspects of the corrosion factor in offshore drilling:

1. Saltwater Exposure

Seawater is highly saline.

Constant exposure to seawater

2. Environmental Conditions

Humidity and Moisture

Temperature variations

3. Galvanic Corrosion

Dissimilar metals in close proximity

4. Microbial Corrosion

Microbiologically Influenced corrosion (MIC) is caused by by-products such as hydrogen sulfide.

5. Mechanical Stress

Wear and Tear

Fatigue

Conclusion

Using Our UNICLAMP Strut and V-BAT™ Pipe Clamps in a marine environment offers the following advantages:

High Strength and Stiffness make it suitable for applications requiring durability and resistance to mechanical stress.

Corrosion Resistance is critical for long-term performance and reliability in saltwater conditions.

Lightweight much lighter than metals like steel or aluminum.

Dimensional Stability across a wide range of temperatures and reducing the likelihood of warping or deformation in marine conditions.

Impact Resistance maintains good impact resistance, which is essential for offshore drilling.

Chemical Resistance to 95% of chemicals, including oils, fuels, and solvents, and highly resistant against hydrocarbons.

UV Resistance helps in maintaining its properties and appearance when exposed to sunlight over 15-20 years.

Cost-effective offering a balance between performance and cost for marine applications.

Ease of Manufacture: This material is easily processed for complex shapes and components.

Resistance to biofouling: Its performance against biofouling includes Surface Smoothness, chemical composition and durability, organic material comparison with other materials, and low nutrient content.

These advantages make our UNICLAMP Strut and V-BAT™ Pipe Clamp imperative for all marine applications, including structural components, fasteners, gears, and fittings.

For more information on Our Uniclamp products, please visit our website.