The primary purpose of the pulp and paper industry is to convert raw materials, primarily wood, into various paper products and cellulose-based materials that are essential for everyday life and numerous industrial applications. This industry produces a wide range of products including writing and printing papers, packaging materials, sanitary products, and specialty papers used in technical applications. Additionally, it generates significant by-products that can be utilized in other sectors, such as lignin for biofuel and chemicals. Through efficient processing and innovation, the pulp and paper industry aims to meet global demands sustainably, emphasizing the use of renewable resources and environmentally friendly practices.

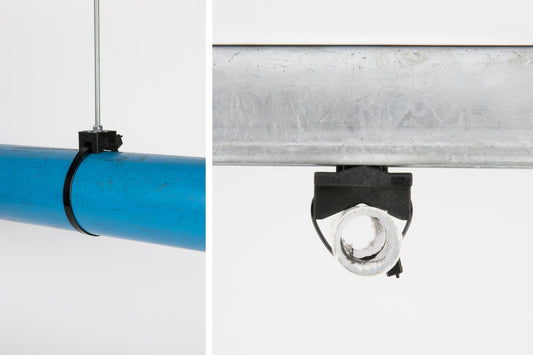

The rigorous specialized demands of the paper and pulp industry are satisfied by Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp which are crucial and Indispensable assets. Resilientness and versatility are requirements the infrastructure supporting pulp and paper manufacturing insists upon. This process commands high levels of optimization and reliability to ensure personnel safety and equipment integrity. Our UNICLAMP clamps fulfill all of these requirements.

Pulp and Paper Industry Overview

The pulp and paper industry remains a significant global sector, balancing traditional practices with modern innovations and sustainability efforts. This industry is vital for providing everyday products, supporting economic growth, and promoting sustainable practices.

Key aspects of the industry:

Raw Materials - Wood, Recycled Paper, and Non-Wood Fibers.

Processes - Pulping, Bleaching and Papermaking

Types of Products - Paper, Paperboard, and Specialty Papers

Environmental Impact - Deforestation, Water Usage and Pollution

Sustainability - Sustainable Forestry, Recycling and Innovative Technologies

Key Players - International Paper, Stora Enso, Sappi, and WestRock

Market Trends - Digitalization, Packaging and Sustainability

Regulations - The industry is subject to environmental regulations regarding emissions, waste management, and sustainable forestry practices.

The Pulp and Paper Industry Involves a Complex System of Pipes

Types of pipes:

Carbon Steel, Stainless Steel, Plastic (PVC, CPVC, HDPE), Alloy (Duplex, Super Duplex) and Rubber-Lined Pipes

These pipes transport:

Water (process and white), Steam, Chemicals (corrosive and aggressive), Bleach, Pulp, Slurry, Effluents, and High-temperature Fluids.

Fasteners are crucial for Maintaining The Structural Integrity and Safety

Their selection depends on environmental conditions, load requirements, and the specific application for the harsh pulp and paper manufacturing environment.

Here are some commonly used fasteners and pipe clamps:

- Anchors

- U-Bolts

- Split Ring

- Clevis Hangers

- Hose Clamp

-

Saddle

These are some competitor clamps used to secure the mentioned pipelines. Our UNICLAMP Strut and V-BAT™ Pipe Clamps can replace all these fasteners, with numerous benefits compared to competitor clamps.

Our UNICLAMP Pipe Clamps are significantly more cost-effective compared to various types of pipe-securing hardware.

Uses and Advantages of Our Uniclamp Strut Pipe Clamp and V-BAT™ Pipe Clamp

The primary purpose of our UNICLAMP Pipe Clamps is to produce high mechanical strength, rigidity, good stability, and corrosive resistance.

Universal Fit and Compatibility

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are designed to accommodate a wide range of pipe sizes, from 3/8" to 5" (9 mm up to 127 mm)

Our UNICLAMP Pipe Clamp’s design makes it compatible with the pipe and fastener materials used in the pulp and paper Industry. Our UNICLAMP Strut and V-BAT™ Pipe Clamps are the ideal fastener choice to accommodate the specific conditions of the manufacturing environment. This compatibility ensures that the same clamp can be used throughout pipe installations, simplifying inventory management and procurement. Whether utilized for small or larger pipe installations, Our UNICLAMP Strut and Our V-BAT™ Pipe Clamps will handle it all.

Durability and Non-Corrosiveness of Our Pipe Clamps

Both Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are manufactured from 30% glass-reinforced nylon 6.6, with tensile strengths of 900 lbs and 1100 lbs (8700 - 12300 psi) respectively, making them suitable for brutal conditions. Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are highly hardy, exhibiting superior mechanical tensile strength and dependability. Our Pipe Clamps are resistant to rust, water, acid, alkaline, and corrosion. Additionally, they provide wear resistance and dimensional stability, making them ideal for humid and corrosive environments commonly faced by the pulp and paper industries. Saving money over time, this durability leads to fewer replacements and lower maintenance costs. Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp UV resistance guarantees a lifespan of 15-20 years, even in harsh environments, eliminating the need for UV-resistant coatings and materials to protect pipeline fasteners.

Pipe installations implement heavy-duty strapping offering stability, strength, and endurance. Stainless steel strapping can support up to 200 lbs, varying thickness based on specific installations. Our nylon cable ties, made from UV-stabilized nylon 6.6, have a carrying capacity of up to 175 lbs. Our clamps and ties are specifically designed to ensure that pipes are securely held in place at all times, which is vital in the pulp and paper industry.

For more information on Strapping and Zip-tie options please check out our blog.

Chemical Exposure

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are acid and alkaline-resistant and 95% to most common chemicals guaranteeing no deterioration of our clamps when directly exposed. No visible signs of degradation or structural chemical changes are evident.

The following chemicals are used in the pulp and paper industry:

Sodium Hydroxide (Caustic Soda), Sodium Sulfide, Sodium Carbonate, Sodium Bisulfite, Sodium Hypochlorite, Sulfurous Acid, Calcium, Magnesium, Ammonium, Chlorine, Chlorine Dioxide, Calcium Oxide, Hydrogen Peroxide, Oxygen, Ozone, and Sulfur.

These chemicals hold no match to our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp.

Certifications

Our UNICLAMP Pipe Clamps are certified by UL2239, UL2043, ISO, RoHS, Reach, and Branz, providing confidence and assurance.

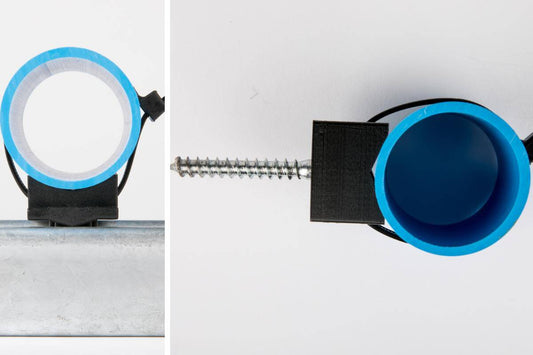

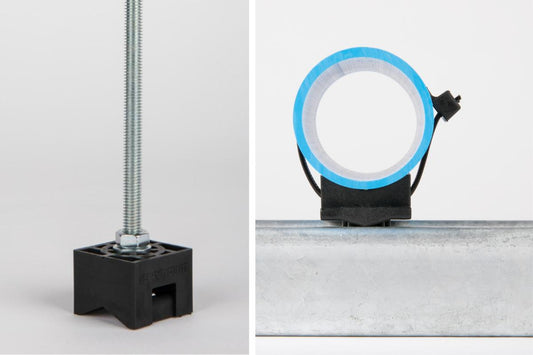

V-BAT™ Pipe Clamp

Time is valuable. Compatible with Hilti tools for fast and effective concrete and surface installations, Our V-BAT™ Pipe Clamp's robustness is evident by not displaying any fractures, shattering, or weakening, validating its capacity for heavy-duty applications. A socket wrench or ratchet is another option for simplifying the installation of Our V-BAT™ Pipe Clamp, facilitating quick setups and reducing labor expenses. The V-BAT™ Pipe Clamp offers versatile applications: flat surfaces, universal hangers, spacers, and Unistrut fixtures.

For more information on the numerous applications of Our V-BAT™ Pipe Clamp check Our Blog.

UNICLAMP Strut Pipe Clamp

Our UNICLAMP Strut Pipe Clamp cuts installation time by up to 83% compared to conventional clamps. Featuring a tool-free, simple place, twist, and strap interlocking system, a cost-effective option for all projects. This clamp can also be mounted as a hanger clamp on the Unistrut.

Our HDPE Sleeve is designed to prevent damage to pipe insulation. HDPE Sleeve Insulation is often employed to avoid cross-contamination and reduce temperature impacts on transport pipes, particularly in extreme climates.

For more information on Our HDPE Sleeve visit Our Blog called Enhancing HVAC System Performance with V-BAT Pipe Clamps and HDPE Sleeves.

Temperature Resistance of our Our UNICLAMP Strut and V-BAT™ Pipe Clamps

Minimum Service Temperature of -22°F to 266°F (-30°C to 130°C) and Maximum Service temperatures of 149°F - 550°F (65°C - 288°C) (MatWeb) authorizing Our UNICLAMP Strut and V-BAT™ Pipe Clamps to be safely and risk-free used in the pulp and paper manufacturing environment, offering great resistance to creep.

For more information on Our Uniclamp Strut Pipe Clamp check out Our Blog.

Temperatures, Pressures, and Vibrations Generated by Pulp and Paper Manufacturing

Temperatures

Mechanical Pulping: ambient to 150-170°C

Chemical Pulping: 150-170°C.

Sulfite Pulping: 130-150°C.

Bleaching: 60-90°C

Cylindrical Dryers: 100-160°C

Infrared Dryers: 200-250°C

Pressures

Mechanical Pulping: atmospheric pressure: 14.64881 psi (1.01 bar)

Kraft Process: 72.5189 psi - 145.038 psi (5-10 bar)

Sulfite Process: 58.0151 psi - 116.03 psi (4-8 bar)

Bleaching: atmospheric pressures: 14.64881 psi (1.01 bar)

Press Section: 145.038 psi - 217.557 psi (10-15 bar)

Drying Section: 43.5113 psi - 116.03 psi (3-8 bar)

Chemical Recovery Boilers: 580.151 psi - 1305.34 psi (40-90 bar)

Vibrations

Mechanical Vibrations - Pulping Equipment: and Paper Machines

Rotating Machinery - Pumps and Fans

Structural Vibrations - Building and Support Structures

Our UNICLAMP Strut and V-BAT™ Pipe Clamps absorb all pressures and vibrations, showing no compressive stress. Therefore vibration monitoring is not required saving time and money.

The UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp

Our UNICLAMP Strut and V-BAT™ pipe clamps are highly versatile products securing pipes, conduits, and tubing to various structures.

The pulp and paper industry depends heavily on piping systems to transport numerous products. Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp provide a tested and tried method of securing pipes, hoses, and equipment to walls, ceilings, and concrete floors. Its robust construction ensures that pipes remain un-moveable, preventing leaks and maintaining the system's integrity.

The Uniclamp Strut and the V-BAT™ pipe clamps allow for trouble-free adjustments. This flexibility is crucial in a manufacturing setting where changes in the process might require repositioning or adding new piping. The clamp’s design and functionality ensure these modifications are made without any extensive downtime.

Safety and Efficiency

The safety and efficiency of the pulp and paper industry process are fundamental. Both our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp contribute boldly to these aspects in several ways:

Leak Prevention: Securely fastened pipes are less likely to leak, crucial in maintaining the quality and consistency of raw material and the finished product. Leaks also pose safety hazards and result in wastage of valuable resources. Employees could be exposed to chemical burns, heat and steam burns, combustible dust, and flammable chemicals. Wet and slippery floors create the possibility of slips and falls:

Ease of Maintenance: Installation of these clamps ensures that maintenance on pipes and equipment is performed rapidly and efficiently. This reduces downtime and ensures that manufacturing operates smoothly. Note that all UNICLAMP pipe clamps are maintenance-free.

Strength and Reliability: The robust construction of the UNICLAMP Strut and V-BAT™ Pipe Clamps ensure withstanding the demanding conditions of the manufacturing operations. This reliability ensures the infrastructure remains safe and functional, protecting the product and personnel.

Corrosion Resistance: Pulp and paper manufacturing deals with constant humid environments and chemical exposure. Our UNICLAMP clamps are up for the challenge!

Conclusion

Ensuring safety and efficiency in pulp and paper manufacturing is paramount for the industry's sustainability and productivity. Investment in safety protocols and making efficiency improvements are crucial for maintaining high production standards and safeguarding its workforce's well-being. The pulp and paper sector thrives continuously in a competitive global market by prioritizing these aspects.

Utilization of our Uniclamp Strut Pipe Clamp and V-BAT™ Pipe Clamp enhances productivity and safety, understanding that these aspects are not negotiable. Our UNICLAMP clamps proudly contribute.

For more information on Our Uniclamp products, please visit our website.