Cement manufacturing is pivotal for producing high-quality cement and supporting the construction of durable and reliable infrastructure. Its advantages include economic growth, quality control, efficiency, and environmental benefits.

The primary purpose is to provide a strong and versatile construction material that ensures structural integrity and safety while enabling innovation and development in construction practices.

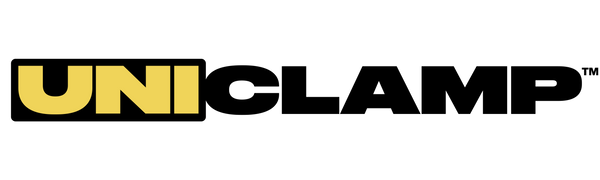

The infrastructure supporting these activities must be robust and versatile. Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp play a crucial role as these UNICLAMP USA products are designed to meet the rigorous demands of the cement industry.

Uses and Advantages of Our Uniclamp Pipe Clamps

Our UNICLAMP Pipe Clamps are implemented when high mechanical strength, rigidity, good stability under heat and pressure, and corrosive resistance are required.

Universal Fit and Compatibility

The UNICLAMP strut pipe clamp and the V-BAT™ pipe clamp are designed to accommodate a wide range of pipe sizes, from 3/8" to 5" (9mm up to 127mm)

The clamp’s design makes it compatible with an assortment of pipe materials, from Carbon Steel, Stainless steel, Ductile Iron, Reinforced Concrete (RCP), Polyvinyl Chloride (PVC), High-Density Polyethylene (HDPE), Fiberglass Reinforced Plastic (FRP), Aluminum, Copper, Brass and Ceramic Lined pipes making it an ideal choice for cement industries. This compatibility ensures that the same clamp can be used throughout the facility, simplifying inventory management and procurement. Whether used for small lines or larger pipes, the UNICLAMP strut and the V-BAT™ pipe clamps handle it all. This versatility reduces the need for multiple types of clamps, streamlining the installation process.

V-BAT™ Pipe Clamp

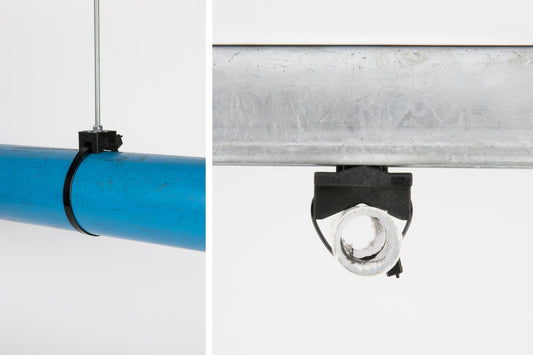

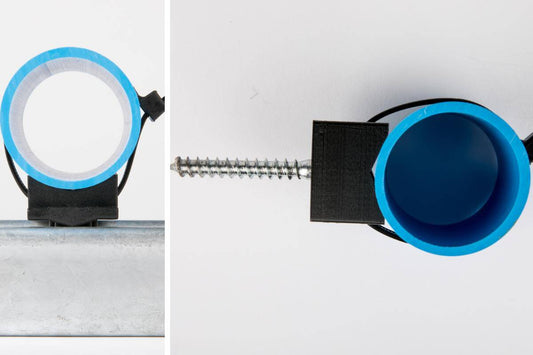

Time is money. Compatible with Hilti guns for quick and efficient installation, demonstrating the V-BAT™ Pipe Clamp robustness, showing no signs of stress, cracks, shattering, or weakening, highlighting its suitability for heavy-duty use. Only a Socket wrench or ratchet is required to ensure an easy installation of the V-BAT™ pipe clamp, thus presenting an easy way of quick installations and cutting labor costs. The V-BAT™ Pipe Clamp is a four-way application: Flat surface, Universal hanger, Spacer, and Unistrut fixture.

UNICLAMP Strut Pipe Clamp

Speed of Installation

Compared to traditional clamps, Our UNICLAMP Strut Pipe Clamp reduces installation time by up to 83%. It is a tool-free uncomplicated place, twist, and strap interlocking system, making it an economical choice for all projects. Our HDS sleeve is available to prevent insolation damage on pipes.

High Durability and Longevity

Both the UNICLAMP strut pipe clamp and the V-BAT™ pipe clamp are constructed from 30% glass-reinforced nylon 6.6, both pipe clamps boast a tensile strength of 900 lb and 1100 lbs respectively to withstand extreme conditions and handling (8700 - 12300 psi) These clamps are extremely rugged, show superior tensile strength, reliable, being rust, water, and acid-proof and exceptionally corrosive resistant. In addition, it also boasts wear and tear resistance and dimensional stability, withstanding the humid and harsh corrosive environment of the cement industry. This durability translates to fewer replacements and lower maintenance costs over time, saving additional expense. Their UV exposure durability ensures a long lifespan of 15-20 years, even in brutal environments.

Secure Pipe Installation

Our clamps and ties are specifically designed to ensure that the pipes used in the cement industry are held firmly in place at all times which is critical for operations. Heavy-duty strapping provides steadiness and strength to the pipe installation. Stainless steel strapping can carry up to 200 lbs! (the thickness depends on your specific installation). Our nylon cable ties, made from nylon 6.6 are UV stabilized, and have a carrying capacity of up to 175lbs!

For more information on Strapping and Zip-tie options please check out our blog.

Temperature Resistance of our Our UNICLAMP Strut and V-BAT™ Pipe Clamps

Minimum Service Temperature of -22°F to 266°F (-30°C to 130°C) and Maximum Service temperatures of 149°F - 550°F (65°C - 288°C) (MatWeb) qualify Our UNICLAMP Strut and V-BAT™ Pipe Clamps to be safely used in the cement manufacturing environment, offering great resistance to creep.

For more information on Our Uniclamp Strut Pipe Clamp check out Our Blog.

In the cement manufacturing process, the Clinker Cooling Systems operate at 212°F- 392°F (100°C-200°C), and the Grinding Mills Operational Temperature ranges from 158°F-212°F (70°C-100°C).

Chemical exposure

Acid and Alkaline resistance and 95% to most common chemicals guarantee no deterioration of these clamps when directly exposed to alkalines and acids. There are no observable degradation nor permanent chemical changes even though the cement process exposes our UNICLAMP clamps to calcium silicates, calcium oxide (CaO), and calcium hydroxide (Ca(OH)₂)

Pressures and vibrations

Pressures

Kiln Pressure: operate under slightly negative pressure (a few millibars below atmospheric pressure)

Clinker Cooling Air Pressure: 1,45038 - 2,90076 psi (0.1-0.2 bar) to ensure effective cooling.

Grinding Mills Operational Pressure: 2175.57 psi. (150 bar) to apply the grinding force needed.

Vibrations

Clinker Cooling Systems experience vibrations due to the movement of the grate and the falling of clinker.

Grinding Mills: Both ball and vertical roller mills generate vibrations. Acceptable vibration levels are 1-5 mm/s.

These parameters are critical for ensuring efficient and safe operation of cement manufacturing processes. Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp absorb all pressures and vibrations not showing any compressive stress.

Certifications

The UNICLAMP strut pipe clamp and the V-BAT™ pipe clamp are certified by UL2239, UL2043, ISO, RoHS, Reach, and Branz, providing peace of mind.

The Uniclamp Strut Pipe Clamp and V-BAT™ Pipe Clamp

The Uniclamp Strut and V-BAT™ pipe clamps are highly versatile products securing pipes, conduits, and tubing to various structures.

The cement industry relies heavily on piping systems to transport raw materials, cooling water, slurry, fuel, exhaust gases, and finished products, collect dust, and manage waste. The Uniclamp Strut and the V-BAT™ pipe clamps provide a reliable method to secure these pipes to walls, ceilings, and concrete floors. Its robust construction ensures that pipes remain securely in place, preventing leaks and maintaining the system's integrity.

The Uniclamp Strut and the V-BAT™ pipe clamps allow for easy adjustments as needed. This flexibility is crucial in a cement manufacturing setting where changes in the process might require repositioning or adding new piping. The clamp’s design and functionality ensure these modifications are made without extensive downtime.

Safety and Efficiency

The safety and efficiency of the cement industry process are essential. Both our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp contribute prominently to these aspects in several ways:

Leak Prevention: Securely fastened pipes are less likely to leak, crucial in maintaining the quality and consistency of raw material and the finished product. Leaks also pose safety hazards and result in wastage of valuable resources. Employees could be exposed to dust, Chemical Burns, and Hazardous Toxic Gases.

Ease of Maintenance: Installation of these clamps ensures that maintenance on pipes and equipment is performed quickly and efficiently. This reduces downtime and ensures that manufacturing operates smoothly. Note that all UNICLAMP pipe clamps are maintenance-free.

Strength and Reliability: The robust construction of the UNICLAMP Strut and the V-BAT™ Pipe Clamps ensure withstanding the demanding conditions of cement manufacturing operations. This reliability ensures that the infrastructure remains safe and functional, protecting the product and personnel.

Corrosion Resistance: Cement manufacturing deals with constant humid environments and chemical exposure. Our UNICLAMP clamps are up for the challenge!

Corrosiveness in the cement process is a significant concern due to the intense operating conditions and the materials involved in the manufacturing process. The key corrosion factors in the cement industry include:

Chemical Exposure: Acids and Alkaline Compounds

The pH scale runs from 1 to 14, with 1 being the most acidic and 14 the most basic, 7 is neutral.

Raw Materials: pH 7 to 8.5

Clinker: Highly alkaline, pH above 12

Cement Powder: Highly alkaline, pH 12 to 13

Moisture: High levels of humidity and water

Abrasive Wear: The abrasive nature of raw materials and cement particles

High Temperatures: Elevated temperatures in kilns and other processing equipment

Salt Exposure: The presence of salts.

Industrial Pollutants: Sulfur dioxide (SO₂), and carbon dioxide (CO₂) can contribute to the formation of corrosive compounds like sulfuric acid (H₂SO₄) and carbonic acid (H₂CO₃).

Mechanical Stress: Mechanical stresses and vibrations can cause cracks and other defects in protective coatings.

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are totally corrosion resistant including acidic and alkaline corrosion preventing pitting, material weakening, and mechanical failure. The use of corrosion-resistant materials or protective coatings is eliminated.

Conclusion

Piping systems are the lifelines of the cement manufacturing process, enabling the efficient, reliable, and safe transport of materials, fluids, and gases. They play a critical role in maintaining process efficiency, ensuring environmental compliance, and enhancing the overall safety and productivity of the plant. Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are proud to contribute positively.

For more information on Our Uniclamp products, please visit our website.