Onshore drilling projects must be carefully managed to minimize environmental impact, ensure safety, and comply with regulatory requirements.

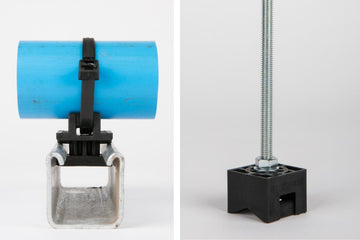

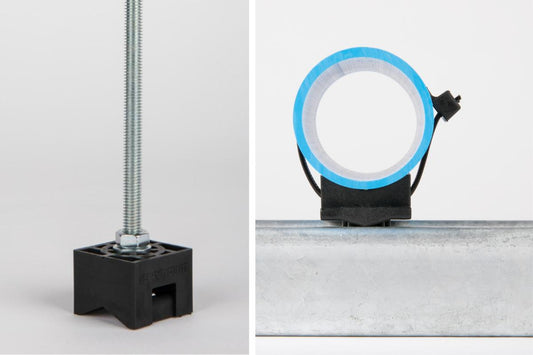

Onshore drilling extracts hydrocarbons, such as crude oil and natural gas from underground reservoirs. Strict safety protocols are followed to protect workers, the public, and the environment during all drilling and production phases. Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are crucial assets designed to meet the rigorous demands of onshore drilling as the infrastructure supporting this activity insists on robustness and versatility. This drilling process commands high levels of efficiency and reliability to ensure safety and equipment integrity.

Key Aspects and Purposes of Onshore Drilling

Onshore drilling encompasses various critical aspects, including site selection, rig setup, and safety measures. The process begins with identifying suitable drilling sites based on geological surveys and data analysis. Rig setup involves assembling drilling equipment, ensuring proper alignment, and adhering to environmental regulations. Safety is paramount in onshore drilling, requiring robust protocols and advanced technologies to prevent accidents and environmental hazards. Implementing tools like the UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp enhances safety by providing secure and reliable solutions for managing drilling operations. These measures collectively contribute to efficient, safe, and environmentally responsible onshore drilling practices.

Onshore Drilling Pipelines and Products Transportation

Clamps Utilized in Onshore Drilling Operations

In onshore drilling, fasteners must be durable, reliable, and capable of handling various environmental conditions, essential for stability in drilling rigs.

Competitor Clamps and Bolts used to Secure Pipe Lines

- U-Bolts

- Rise Pipe Clamps

- Heavy-duty Clamps

- Vibra-Clamps

- Anchor Bolts

These are some competitor clamps used to secure the six mentioned pipelines. Our UNICLAMP Strut and V-BAT™ Pipe Clamps can replace all these fasteners, with numerous benefits compared to competitor clamps.

Our UNICLAMP Strut and V-BAT™ Pipe Clamps are significantly more cost-effective compared to various types of pipe securing hardware.

U-Bolts: For instance, a stainless steel U-bolt from Ferguson costs approximately $61.89 for a 4-inch size, and up to $252.04 for larger sizes (Ferguson) (Empire Industries). Other suppliers offer U-bolts in the range of $46.65 to $158.69 based on the specifications and material quality (Piping Technology & Products, Inc.).

Pipe Hangers: These are available at various price points, with some galvanized pipe hangers costing around $5 each depending on the size and complexity (The Home Depot).

In comparison, Our UNICLAMP Strut and V-BAT™ Pipe Clamps are priced at $2.49 each, or $2.20 when bought in bulk. This makes Our Uniclamps substantially cheaper, offering savings of up to 98.15% compared to some pipe clamps and 77% compared to standard pipe clamps (Uniclamp USA) (Uniclamp USA).

To Purchase Our Uniclamp Products click here.

Uses and Advantages of Our Uniclamp Strut Pipe Clamp and V-BAT™ Pipe Clamp

Our UNICLAMP Pipe Clamps are applied when high mechanical strength, rigidity, good stability, pressure, and corrosive resistance are required.

Universal Fit and Compatibility

Our UNICLAMP strut pipe clamp and V-BAT™ pipe clamp are designed to accommodate a wide range of pipe sizes, from 3/8" to 5" (9 mm up to 127 mm)

Our UNICLAMP Pipe Clamp’s design makes it compatible with an assortment of pipe materials, including steel (High-strength alloy Carbon alloy, Stainless) pipes, polyethylene (PE), PVC, Fiberglass Reinforced Plastic (FRP) and Ductile Iron pipes used in the onshore drilling environment. The specific extreme conditions of the drilling environment make Our UNICLAMP Strut and V-BAT™ Pipe Clamps the ideal fastener choice. This compatibility ensures that the same clamp can be used throughout pipe installations, simplifying inventory management and procurement. Whether used for small or larger transportation pipes, Our UNICLAMP Strut and Our V-BAT™ Pipe Clamps will handle it all.

Durability and Non-Corrosiveness of Our Pipe Clamps

Both Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are manufactured from 30% glass-reinforced nylon 6.6, with tensile strengths of 900 lbs and 1100 lbs respectively, making them suitable for profound conditions (8700 - 12300 psi). Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are highly durable, demonstrating superior tensile strength and reliability. Our Pipe Clamps are resistant to rust, water, acid, and corrosion. Additionally, they provide wear resistance and dimensional stability, making them ideal for humid and corrosive environments commonly faced by onshore drilling. This durability leads to fewer replacements and lower maintenance costs, saving money over time. Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp UV resistance guarantees a lifespan of 15-20 years, even in harsh environments, eliminating the need for UV-resistant coatings and materials to protect pipeline fasteners.

Heavy-duty Strapping Options

Pipe installations use heavy-duty strapping offering stability and strength. Stainless steel strapping can support up to 200 lbs, with thickness varying based on specific installations. Our nylon cable ties, made from UV-stabilized nylon 6.6, have a carrying capacity of up to 175 lbs. Our clamps and ties are specifically designed to ensure that pipes are securely held in place at all times, which is critical in onshore drilling.

For more information on Strapping and Zip-tie options please check out our blog.

Chemical Exposure

Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are acid resistant and 95% to most common chemicals guarantee no deterioration of our clamps when directly exposed to alkalines and acids. There are no visible signs of degradation or permanent chemical changes. Our UNICLAMP clamps are tremendously resistant to Hydrocarbons.

Certifications

Our UNICLAMP Strut V-BAT™ Pipe Clamps are certified by UL2239, UL2043, ISO, RoHS, Reach, and Branz, providing confidence and assurance.

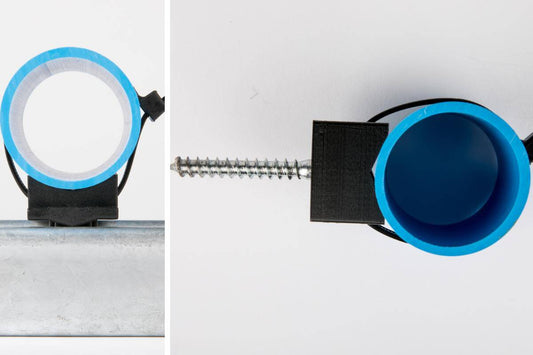

V-BAT™ Pipe Clamp

Our mission is to reduce your costs while increasing installation speed, that is exactly why you need Our V-BAT™ Pipe Clamp. Compatible with Hilti tools for fast and effective concrete and surface installations, Our V-BAT™ Pipe Clamp's robustness is evident by not displaying any fractures, shattering, or weakening, proving its capacity for heavy-duty applications. A socket wrench or ratchet is another option for simply installing Our V-BAT™ Pipe Clamp, facilitating quick setups and reducing labor expenses. The V-BAT™ Pipe Clamp offers versatile applications: flat surfaces, universal hangers, spacers, and Unistrut fixtures.

For more information on the numerous applications of Our V-BAT™ Pipe Clamps check out Our Blog.

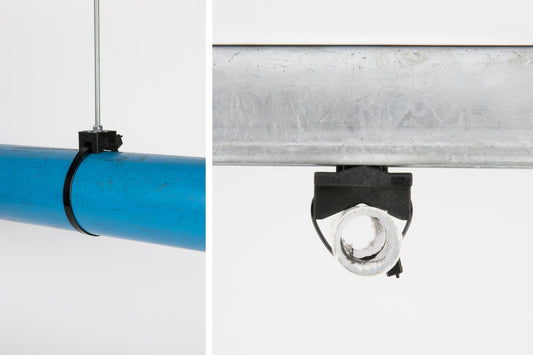

UNICLAMP Strut Pipe Clamp

Our UNICLAMP Strut Pipe Clamp cuts installation time by up to 83% compared to conventional clamps. Featuring a tool-free, simple place, twist, and strap interlocking system, a cost-effective option for all projects. This clamp can also be mounted as a hanger clamp on the Unistrut. Our HDPE Sleeve is designed to prevent damage to pipe insulation. HDPE Sleeve Insulation is often employed to avoid cross-contamination and reduce temperature impacts on transport pipes, particularly in extreme climates.

For more information on Our HDPE Sleeve check out Our Blog called Enhancing HVAC System Performance with V-BAT Pipe Clamps and HDPE Sleeves.

Temperature Resistance of our Our UNICLAMP Strut and V-BAT™ Pipe Clamps

Minimum Service Temperature of -22°F to 266°F (-30°C to 130°C) and Maximum Service temperatures of 149°F - 550°F (65°C - 288°C) (MatWeb) qualify Our UNICLAMP Strut and V-BAT™ Pipe Clamps to be safely used in the onshore drilling environment, offering great resistance to creep.

For more information on Our Uniclamp Strut Pipe Clamp check out Our Blog.

Temperatures, Pressures and Vibrations Produced by Onshore Drilling

Surface Temperature:

Arctic regions: -40°C/F or lower

Desert regions: exceeding 122°F (50°C).

Downhole Temperature:

Averages 1.4-1.6°F per 100 feet (25-30°C per kilometer) of depth.

In deep wells, 302°F (150°C) and, in some cases, 392°F (200°C) or more.

Surface Pressure:

At sea level, approximately 14.7 psi (101.3 kPa).

Downhole Pressure:

Downhole pressure can exceed 10,000 psi (68.95 MPa) in deep wells.

Surface Vibrations:

Vibrations generated by heavy machinery operation and the drilling rig itself, affect equipment and the surrounding environment.

Downhole Vibrations:

As the drill bit cuts through rock, it generates vibrations.

Our UNICLAMP Strut and V-BAT™ Pipe Clamps absorb all vibrations not showing any stress.

Our Uniclamp Strut Pipe Clamp and V-BAT™ Pipe Clamp in the Onshore Drilling Environment

Our Uniclamp Strut and V-BAT™ Pipe Clamps are highly versatile products securing pipes, conduits, and tubing to various structures. Here’s how it is typically employed in onshore drilling.

Piping Systems Installation: Extensive piping systems are required to transport hydrocarbons, such as crude oil and natural gas. Our Uniclamp Strut and V-BAT™ Pipe Clamps provide a proven reliable method to secure pipes to walls, ceilings, and floors. Our clamps can be attached to various materials including concrete, wood, and metal surfaces, ensuring versatility and robustness in different installation environments including intense cold or heat. Exceptionally strong construction of Our Uniclamp Strut and V-BAT™ Pipe Clamps guarantees that pipes stay firmly in place, preventing any leaks and preserving the system's integrity.

Easy Adjustments: Our Uniclamp Strut and V-BAT™ pipe clamps allow for easy adjustments required on demand. This flexibility is applied where material or environmental changes might require repositioning or adding new piping. Uniclamp’s design and functionality ensure these modifications are made without extensive downtime.

Safety and Efficiency

The safety and efficiency of the onshore drilling process are preeminent. Both Our UNICLAMP Strut and V-BAT™ Pipe Clamp contribute significantly to both these aspects in several ways:

Leak Prevention: Securely fastened pipes with Our UNICLAMP Strut and V-BAT™ Pipe Clamp are less likely to leak, which is fundamental and crucial in maintaining the quality, consistency, and integrity of the drilling process. Leaks pose safety and health hazards and result in wastage of valuable resources. A leak can lead to an explosion if it comes into contact with an ignition source. Workers can be exposed to hydrocarbons causing respiratory issues, skin and eye irritation, central nervous system (CNS) effects, carcinogenicity, reproductive and developmental toxicity, and organ damage. Leaks could result in injuries, slips, trips, and falls.

Ease of Maintenance: Installation of Our UNICLAMP Strut and V-BAT™ Pipe Clamps ensures that maintenance on the pipes and equipment can be performed quickly and efficiently. This reduces downtime and ensures that the drilling process operates smoothly. Note that all UNICLAMP pipe clamps do not require any maintenance.

Strength and Reliability: The robust construction of Our UNICLAMP Strut and V-BAT™ Pipe Clamps can withstand demanding conditions. High winds, rain, snow, and ice impose additional mechanical stress on pipelines and fasteners. The provided reliability of Our UNICLAMP Strut and V-BAT™ Pipe Clamps ensures that the infrastructure remains safe and functional, protecting the operation and personnel.

Corrosion Resistance: Transportation pipes are manufactured to withstand harsh and humid environments and chemical exposure. Vulnerability to moisture, oxygen, and pollutants accelerates rust formation and galvanic corrosion. Our UNICLAMP clamps are completely non-corrosive, there is no need for cathodic protection or protective coatings or linings like epoxy, polyurethane, or zinc to create a barrier against corrosive elements.

Conclusion

The onshore drilling process generates vibrations, pressures, and temperatures necessitating robust fasteners. Atmospheric influences such as corrosion, temperature extremes, UV radiation, wind, weather, and seismic activity radically affect pipeline integrity Our UNICLAMP Strut pipe clamp and V-BAT™ Pipe Clamps ensure long-term endurance and strength and guarantee safe and secure pipe installations and drilling operational efficiency that you can rely upon for years.

For more information on Our Uniclamp products, please visit our website.