In the world of construction and plumbing, efficiency is paramount. Imagine an innovative product that can streamline installation processes, save time, reduce costs, and enhance productivity. No need to imagine, The V-BAT Pipe Clamp by Uniclamp USA is a revolutionary product making waves in the industry. This innovative pipe clamp is redefining the installation of pipes globally, the benefits of the V-BAT will inspire you to increase your productivity.

The Evolution of Pipe Clamps

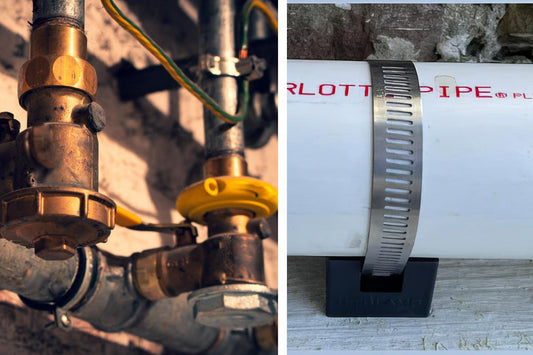

Pipe clamps have been essential in the construction and plumbing industries for over 100 years, securing pipes in various applications. Traditional pipe clamps, while effective, often come with limitations that can reduce installation efficiency. Issues such as complicated installation processes, lack of adjustability, and difficulty accommodating different pipe sizes have been persistent challenges.

Enter the V-Bat: A Game-Changer in Pipe Installation

The V-Bat is a paradigm shift in pipe clamp design and functionality. Engineered with precision and innovation, this revolutionary clamp offers a host of features that address the shortcomings of traditional clamps while introducing new levels of efficiency and versatility. Upgrade your business with the V-BAT pipe clamp, you will never need a conventional pipe clamp again.

Universal Hanger Clamp

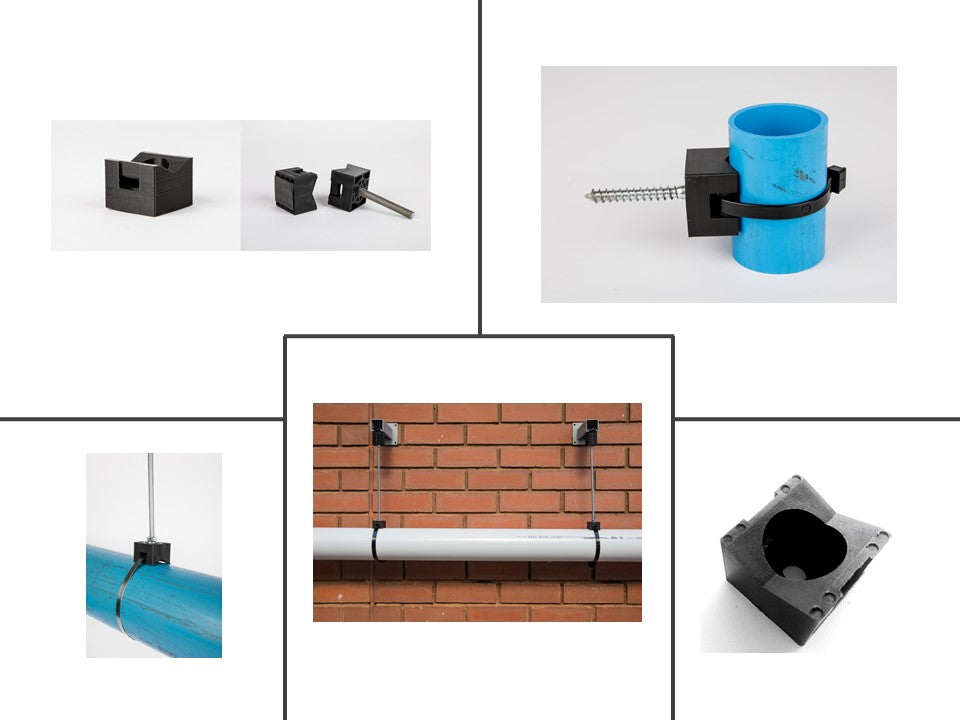

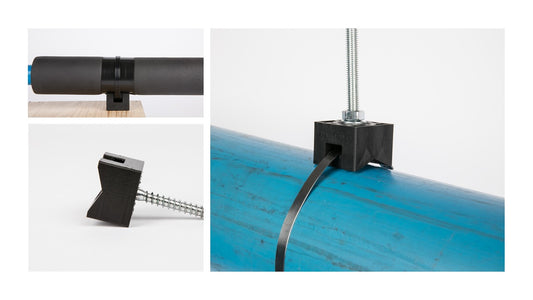

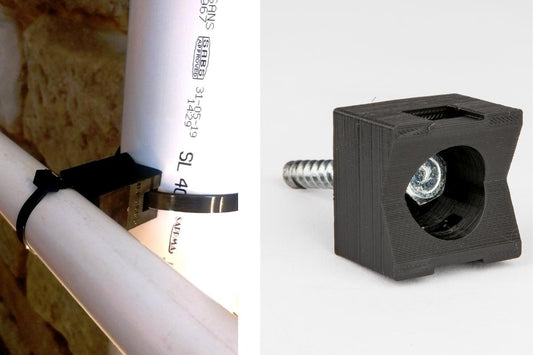

Picture this: you are in the midst of a plumbing installation project and juggling multiple hanger clamps to accommodate different pipe diameters. It's a hassle, at the very least. But with the Uniclamp V-BAT, those days are behind you. The V-Bat's ingenious design accommodates any pipe size from 3/8" up to 5 inches, allowing you to use one pipe clamp for all your projects.

But that's not all. The V-BAT isn't limited to flat surfaces; it excels as a hanger clamp when used on threaded rods, adding an extra layer of adaptability to your toolkit.

Universal Spacer: Streamlining Installation with Ease

With the Uniclamp V-BAT Pipe clamp, you will never have to buy a pipe spacer. Your solution is the uniquely designed back-to-back configuration or double-strapped single configuration of the V-BAT. The innovative design simplifies the installation process while saving you the cost of pipe clamp spacers.

Enhanced Adjustability

One of the standout features of the V-Bat is its unparalleled adjustability. Unlike conventional pipe clamps that require separate components for different pipe sizes, the V-BAT boasts a unique design that allows for seamless adjustment for pipes from 3/8" up to 5” with various different strapping options. This eliminates the need for multiple pipe clamp sizes, simplifying your inventory management process, and decreasing project costs.

One clamp, to do your entire project.

Quick and Easy Installation

Time is of the essence in construction projects, and the V-Bat is designed with this in mind. Its intuitive design enables rapid installation, allowing contractors to complete pipe installations in a fraction of the time compared to traditional clamps.

As a matter of fact, it's so strong that you can even shoot it into concrete with a Hilti Concrete Nailer.

The V-BAT streamlines installation and minimizes labor costs, making the V-Bat a cost-effective solution for projects of any scale.

Durable and Reliable Construction:

Durability is non-negotiable when it comes to construction materials and equipment. The V-BAT is constructed from 30% Glass-Reinforced Nylon making it rust-proof, waterproof, and acid-proof, & it has a 15-year solar lifespan, ensuring robustness and reliability in the most demanding environments.

Whether in residential, commercial, or industrial settings, contractors can trust the V-BAT to secure long-lasting pipe support.

Versatility in Multiple Industries

Join the many global companies that use Uniclamp’s V-BAT daily. With its unique “V” design and multiple uses The V-BAT is changing the way industries function. Uniclamp’s V-BAT pipe clamp supplies to plumbing, electrical, refrigeration, irrigation, and hydraulic sectors globally.

Safety and Compliance

Compliance with industry standards and regulations is crucial in construction projects. The V-Bat is engineered to meet all relevant safety and performance standards, ensuring peace of mind for contractors and project managers. Its robust construction and secure grip minimize the risk of pipe slippage or failure, enhancing overall safety on job sites.

The V-Bat is UL 2239 & UL 2043 listed. It's also compatible with plenum spaces.

Uniclamp V-Bat vs Traditional clamps

Uniclamp's V-BAT is a versatile solution priced at a mere $2.20 when purchased in bulk. Traditional clamps are available at a staggeringly higher price tag of $38.08. At only $2.20 per clamp, you'll be saving at least 98.15% in costs compared to competitor clamps.

But it's not just about the price; Uniclamp’s V-BAT pipe clamp features numerous benefits.

With a lifespan of 15 years or more, Uniclamp outshines the Split Pipe Clamp, which typically lasts around five years.

And let's not forget Uniclamp's confidence in its product, offering a 105% and 365-day risk-free guarantee. When you need to secure pipes efficiently, economically, and reliably, Uniclamp’s V-BAT pipe clamp stands head and shoulders above the rest.

Conclusion

The UniClamp V-Bat represents a groundbreaking advancement in pipe clamp technology, revolutionizing the way pipes are installed in construction projects. With its unmatched adjustability, quick installation, durability, versatility, and compliance with industry standards, the V-BAT offers a compelling solution for contractors seeking to enhance efficiency and productivity.

As the construction industry continues to evolve, innovative products like the V-BAT are poised to play a crucial role in shaping its future.

Get yours today by clicking the button below, and revolutionize your business.