When securing pipes in various installations, choosing the right pipe clamp and understanding how to install it correctly is crucial to ensure the integrity and stability of the installation.

Whether you're working on a plumbing, HVAC, or electrical project, the effectiveness of your installation depends significantly on the quality of the clamps used and the precision of their placement.

This guide will instruct you through the process of hanging pipe clamps, focusing on the innovative V-BAT™ Pipe Clamp as an ideal solution.

Understanding Pipe Clamps and Their Importance

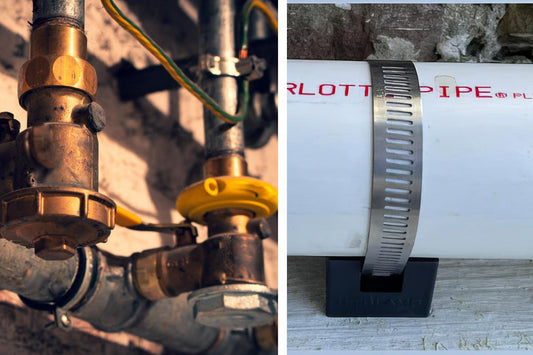

Pipe clamps are essential in securing pipes to a fixed structure, preventing movement, and ensuring stability. They are used in a variety of applications, including:

- Plumbing: To secure water and waste pipes.

- HVAC: To support pipes in the Refrigeration Industry.

- Electrical: To secure conduit and cable installations.

- Industrial: To support piping in manufacturing and processing plants.

-

Solar: To secure conduit and cable installations.

-

Oil & Gas: To support piping in this industry.

-

Telecommunication: To secure conduit and cable installations.

- Mining: Used in open and underground installations.

Correctly installed pipe clamps help prevent damage to pipes, reduce vibration, and ensure the longevity and safety of all these installations.

Introducing the V-BAT™ Pipe Clamp

The V-BAT™ Pipe Clamp from Uniclamp USA is a versatile and durable solution designed to accelerate the process of pipe installations. This clamp stands out due to its universal fit, robust construction, and ease of installation. Here are some of the V-BAT™ Pipe Clamp key features:

Universal Fit

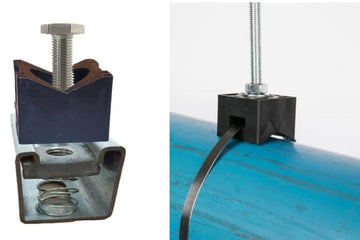

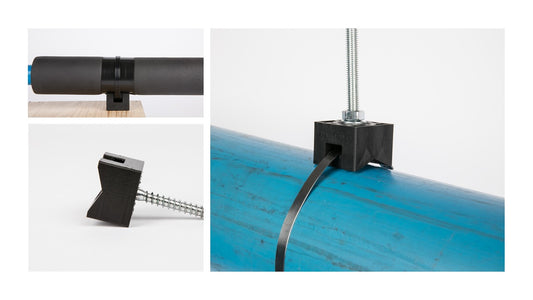

The V-BAT™ accommodates pipe sizes ranging from 3/8" to 5" (9 mm to 127 mm), making it suitable for hanger and spacer functions. The V-BAT™ has a threaded rod/bolt hole size of 5/16" but can be expanded to 3/8".

Durable material

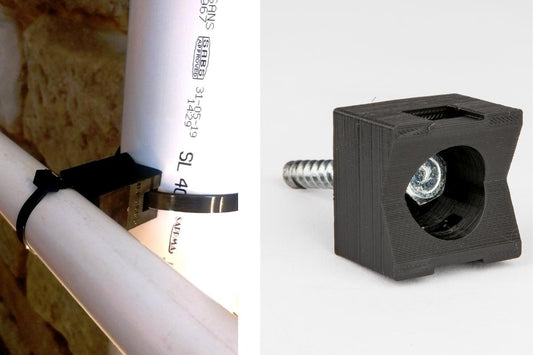

The V-BAT™ is made from robust, lightweight 30% glass-reinforced nylon with added UV stabilizers and boasts a shear tensile strength of 1100 lbs. The V-BAT™ Pipe Clamp is non-corrosive, rust-proof, waterproof, and acid-proof. It also has a 15-year solar lifespan, ensuring long-lasting outdoor applications.

The V-BAT™ Pipe Clamp has undergone rigorous strength tests to ensure its reliability and durability in various applications. One notable test involved using a Hilti gun to install the V-BAT™ clamp directly into concrete. This test demonstrated the clamp's robustness, showing no signs of stress, cracks, shattering, or weakening, highlighting its suitability for heavy-duty use.

Different Types of Strapping to Secure the V-BAT™ Pipe Clamp

The V-BAT™ Pipe Clamp can be installed using nylon/stainless zip ties or can support a 1/2-inch hose clamp. When using the V-BAT™ Pipe Clamp as a Hanger Clamp we recommend securing the V-BAT™ with a hose clamp. Our Lab Results show that securing Our V-BAT™ Pipe Clamp with a 1/2-inch hose clamp has a carrying capacity of over 1500 lbs, however, our manufacturing specifications recommend limiting the carrying capacity to 1100 lbs.

Want to know what strapping options to choose for your pipe installations click here.

Incorporate Our HDPE Sleeve to Improve Installation

Our HDPE Sleeve was designed to distribute the force of strapping along the Armorflex, ensuring a secure installation without compressing the insulation. Our HDPE Sleeves can also prevent cross-contamination between the strapping and the pipe, simply wrap the HDPE sleeve around the pipe and secure.

Want to know more about Our HDPE Sleeve check out our blog.

Cost-Effective

At $2.20 per clamp on bulk purchases, the V-BAT™ Pipe Clamp offers a cost-effective alternative to traditional metal clamps without compromising quality or performance. Our V-BAT™ is a universally sized clamp that simplifies inventory management and reduces the need for multiple clamps.

For more information on Our V-BAT™ Pipe Clamp click here.

Step-by-Step Guide to Hanging Pipe Clamps

Preparation

Before you begin, ensure that you have all necessary tools and materials, including:

- Drilling machine with required size drill bits

- V-BAT™ Pipe Clamps

- Nylon or stainless steel zip ties depending on the requirement

- Hilti gun (if using)

- Measuring tape

- Level

-

Socket wrench or ratchet

- Anchors and screws (if mounting on a wall or ceiling)

Measure and Mark

Accurate measurement and marking are crucial for ensuring the pipes are properly aligned and securely fastened.

- Measure the Pipe Path: Determine the path of the pipes, including any turns or bends.

- Mark the Clamp Locations: Mark the locations where the clamps will be installed. Ensure that the spacing between clamps is appropriate for the type and size of the pipe.

Install the Anchors

If you are mounting the clamps on a wall or ceiling, you'll need to install anchors to provide a secure base for the screws. Here's how:

- Drill Pilot Holes: Using a drill bit that matches the size of your anchors, drill pilot holes at the marked locations.

- Insert Anchors: Insert the anchors into the pilot holes, ensuring they are flush with the surface.

Attach The V-BAT™ Clamps

- Position The V-BAT™ Clamp

- Secure The V-BAT™ Clamp: Tighten the 5/16" or 3/8" bolt until the clamp is securely fastened and at the required height. If using a Hilti gun, follow the manufacturer's instructions for proper installation.

- Repeat: Repeat the process for each clamp location.

Install the Pipes

With the V-BAT™ Clamp installed, you can quickly and easily install the pipes.

- Simply secure the pipe to the V-BAT™ Clamp with a 1/2-inch hose clamp.

Check Alignment and Adjust

Once all pipes are installed, check the alignment and make any necessary adjustments:

- Use a Level: Check that the pipes are level and properly aligned.

- Adjust as Needed: If any pipes are misaligned, loosen the strapping, adjust the pipes, and retighten the strapping.

Final Inspection

Conduct a final inspection to ensure everything is secure and properly aligned:

- Check for Stability: Ensure all pipes are securely fastened

- Inspect for Leaks: If applicable, check for leaks at pipe joints and connections.

Advantages of Using the V-BAT™ Pipe Clamp

The V-BAT™ Pipe Clamp offers several advantages over traditional metal clamps.

Versatility: Its unique universal fit reduces the need for multiple clamp sizes.

Durability: Resistant to rust, acids, and UV radiation, the V-BAT™ Pipe Clamp offers a 15-year lifespan, even in harsh environments.

Cost-Effective: At only $2.20 per clamp, it provides a cost-effective solution without sacrificing quality.

Multiple Applications and Ease of Installation: The 3-in-1 V-BAT™ is compatible with several mounting applications, quick to install saving you time and labor costs. and efficient installation.

Conclusion

Hanging pipe clamps is a straightforward process that, when done correctly, ensures the stability and longevity of your piping installations. The V-BAT™ Pipe Clamp from Uniclamp USA offers a versatile, durable, and cost-effective solution that simplifies the installation process while providing reliable performance. By following the steps outlined in this guide, you will achieve professional-quality results in all your projects.

For more information on the V-BAT™ Pipe Clamp and to purchase this innovative product, visit Uniclamp USA. Whether working on residential, commercial, or industrial projects, the V-BAT™ Pipe Clamp is the ultimate solution for all your pipe clamping needs.

Our mission is to save you time, and money, which will be accomplished when you purchase the V-BAT™ Pipe Clamp.