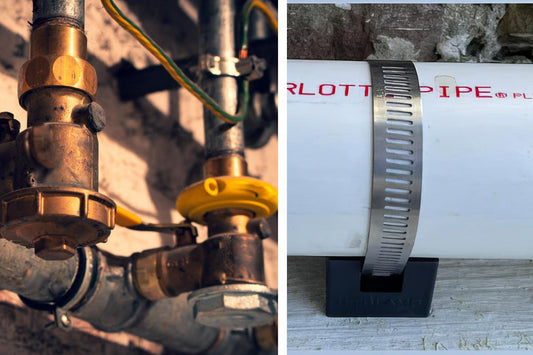

Our UNICLAMP V-BAT™ Pipe Clamp is better than regular universal-sized pipe clamps because it can easily fit different pipe sizes and has special features like metal zip ties for extra strength. Unlike standard clamps that need to be tightened by hand and might not always fit well, the V-BAT™ is more efficient, reliable, and flexible, making it a great solution for securing pipes in many different situations.

With over 30 years of experience as a tradesman and Health and Safety officer, I have never found a pipe clamp as strong and easy to use as the V-BAT™. I’m confident it will meet all your needs.

Understanding Universal-Sized Pipe Clamps

Universal-sized pipe clamps have been used in homes and industries for a long time. They are popular because they can fit different sizes of pipes. These clamps usually have an adjustable band or strap that can be tightened around pipes of various sizes. This feature makes them versatile and means you don’t need to keep a lot of different-sized clamps on hand. However, while universal pipe clamps are useful, they have limitations.

Limitations of Universal-Sized Pipe Clamps

Limited Precision Fit

Universal-sized pipe clamps are made to fit many different pipe sizes, but this flexibility can come at a cost. Unlike custom-sized clamps that fit a specific pipe perfectly, universal clamps might not fit as snugly. This can cause the pipe to move or slip, especially in high-pressure situations or vibrations, making the setup less stable and safe.

Reduced Holding Power

Since universal clamps are not made for a specific pipe size, they might not hold the pipe as tightly as a clamp designed just for that pipe. This can make them less effective, especially where a strong, unmovable connection is really important. In critical systems, like those in factories or areas with high pressure, this could lead to problems like leaks, vibrations, or the pipe moving out of place.

Risk of Over-Tightening

To compensate for the less perfect fit, people installing the clamps might tighten them too much, hoping to make the connection more secure. But tightening too much can damage the pipe, especially if made from softer materials like plastic or thin metal (copper). This could cause the pipe to bend, crack, or even break, leading to leaks or other serious issues.

Material Compatibility Issues

Universal clamps might not always be made from materials that work well with all types of pipes. For example, a clamp that rusts easily would not be a good choice for pipes that carry corrosive substances or are in wet environments. This can make the clamp wear out faster and stop working properly caused by corrosion.

Aesthetic Concerns

In some setups, especially where the pipes are visible, it does make a difference how the clamp looks. The setup could look less attractive as the Universal clamps might be bulkier or less sleek compared to custom-fitted options. This is particularly important in places like homes or offices where appearance is important.

Incompatibility with Specialized Pipes

Universal-sized clamps aren’t always the right fit for special or unusual pipes. Pipes that have unique shapes, are heavily insulated or have other special features might not fit well in a universal clamp. In these cases, a custom or specialized clamp would be needed to ensure everything fits securely.

Higher Inventory Costs

While universal clamps can cut down on the need to stock different sizes, you might still need to keep different types of universal clamps on hand to cover all possible uses. For businesses that use many different kinds of pipes, this could lead to higher costs for keeping a variety of clamp designs and materials in stock.

Performance Issues in Specialized Applications

In very specific situations, like those with extreme temperatures, high pressure, or dangerous materials, the compromise of using a universal clamp might not be good enough. Custom clamps made for these specific conditions are often needed to meet strict safety and performance standards, and universal clamps might not always do the job.

Inconsistent Installations

Because universal clamps are meant to fit many different pipes, they might lead to inconsistent results. In situations where everything needs to be precise and uniform, like in large industrial projects, the slight differences in how universal clamps fit and hold pipes could lead to variations in how well the system works.

The Advantages of the UNICLAMP V-BAT™ Pipe Clamp

Our UNICLAMP V-BAT™ Pipe Clamp solves these problems by providing a better and more advanced way to secure pipes of different sizes. Here's how the V-BAT™ works better than traditional universal pipe clamps:

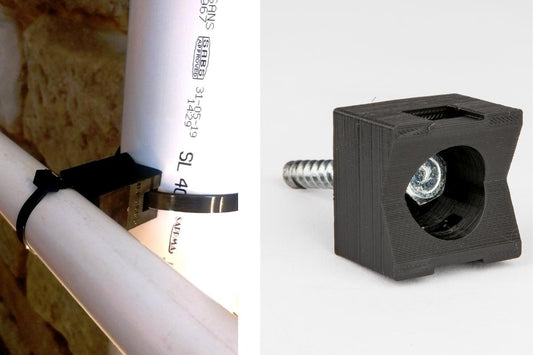

Superior Durable Construction: Our V-BAT™ Pipe Clamp is made from 30% glass-reinforced nylon 6.6, making it very strong with a tensile strength of 1,100 pounds. This means it's built to last, even in tough conditions. The V-BAT™ Pipe Clamp is highly durable, offering great strength and reliability. It doesn’t rust and is resistant to water, acids, alkalines, and corrosion. Plus, it stands up well to wear and tear, keeping its shape and stability, which is especially important in humid and corrosive environments.

No matter what industry you are in, if you work with pipes, you need a clamp that won’t break or wear out. The V-BAT™ is built to last, so it can handle heavy use without losing grip or strength. This durability saves you money in the long run because you would not need to replace it often, and it requires no maintenance.

UV Resistant: Our V-BAT™ Pipe Clamp is UV-resistant, lasting 15-20 years, even in tough conditions. This means you would not need to add extra UV-resistant coatings or materials to protect your pipeline clamps.

Accommodates Different-Sized Pipes: Its versatile design is one of the best things about this clamp. Our UNICLAMP V-BAT™ Pipe Clamp is made to fit many pipe sizes, from 3/8 inch to 5 inches (9 mm to 127 mm). You can use one V-BAT™ for different jobs, making it a flexible and convenient choice. Whether you’re working with small or large pipes, our UNICLAMP V-BAT™ Pipe Clamp can handle it all. Its versatility and adjustability mean you don’t need a bunch of different clamps, making the installation process easier.

Safety is a top priority in any construction or installation project. Our V-BAT™ Pipe Clamp provides a reliable way to secure pipes to walls, ceilings, unistruts, and floors. It can be attached to concrete, wood, rock, and metal, making it versatile and strong in different environments, even in extreme cold or heat. The V-BAT™ helps create a safer work environment by keeping pipes securely in place, reducing the risk of accidents or damage, preventing leaks, and keeping the system safe from potentially dangerous situations.

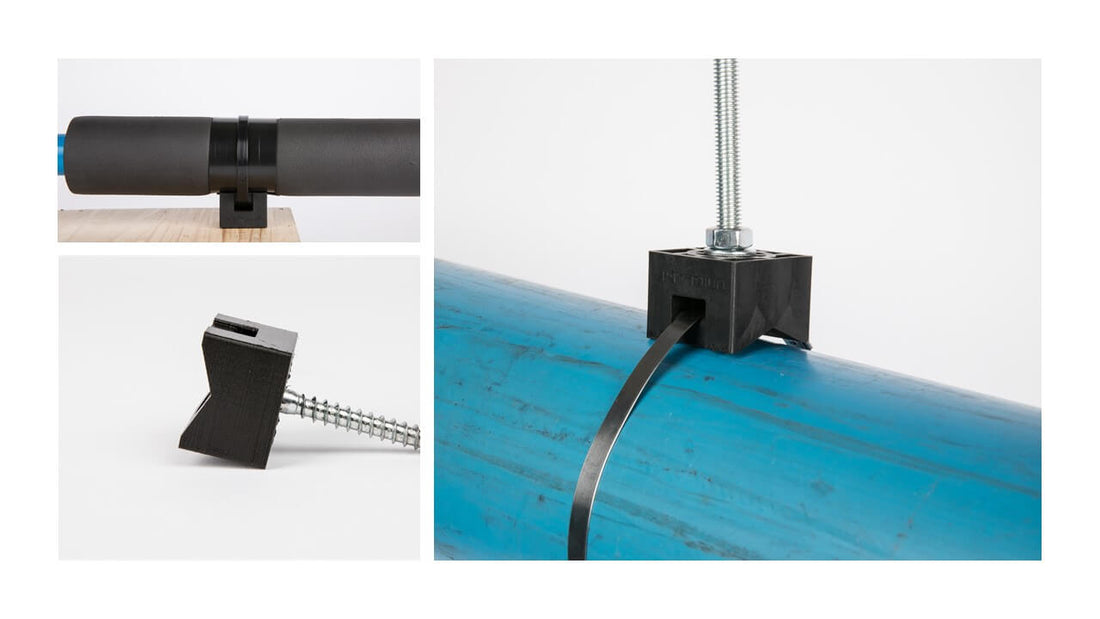

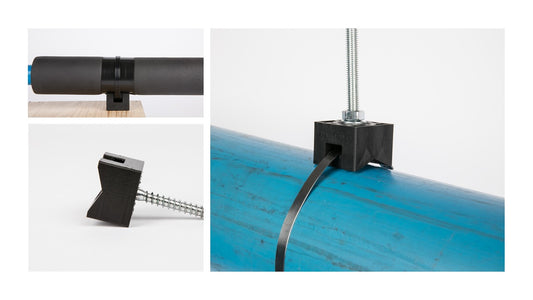

Integration of Metal Zip Ties: The main job of a pipe clamp is to hold pipes securely in place, and the V-BAT™ does this very well. A strong grip keeps pipes from slipping or moving, which is important in ensuring pipes are lined up correctly and safely. Heavy-duty strapping is used in pipe installations to add stability, strength, and durability. Stainless steel strapping can support up to 200 pounds, with different thicknesses depending on what’s needed. Our nylon cable ties, made from UV-stabilized nylon 6.6, can hold up to 175 pounds. Our clamps and ties are designed to securely keep pipes in place, essential for safe operation. This makes the V-BAT™ ideal for use in challenging environments where reliability is paramount.

For more information on Strapping and Zip-tie options please check out our blog.

HDPE Sleeve: Our HDPE Sleeve is made to protect pipe insulation by spreading the pressure of the strapping along the Armorflex. It helps prevent cross-contamination and reduces temperature changes in plumbing pipes, especially in extreme climates. With this sleeve, you won’t need to cut away the insulation, and it won’t get squeezed by the strapping.

Just wrap the sleeve around the pipe, tighten the strap, and complete the installation!

Enhanced Safety: Safety is paramount in any construction or installation project. Our UNICLAMP V-BAT™ Pipe Clamp provides a reliable way to secure pipes to walls, ceilings, unistruts, and floors. It can be attached to concrete, wood, rock, and metal, making it versatile and strong in different environments, even in extreme cold or heat. The V-BAT™ helps create a safer work environment by keeping pipes securely in place, reducing the risk of accidents or damage, preventing leaks, and keeping the system safe from potentially dangerous situations.

Easy Installation: Installing pipe clamps can be tricky, but the V-BAT™ makes it easy. Since time is valuable, our V-BAT™ Pipe Clamp is designed to work with Hilti tools for quick and effective concrete and surface installations. It’s strong and won’t crack, shatter, or weaken, making it great for heavy-duty use. You can also use a socket wrench or ratchet to install this pipe clamp easily, which helps speed up the process and lower labor costs. The V-BAT™ Pipe Clamp can be used for many things, like flat surfaces, universal hangers, spacers, and Unistrut fixtures.

This easy installation saves time and effort, making it perfect for professionals and DIY enthusiasts.

Corrosion and Chemical Resistance: Our V-BAT™ Pipe Clamp is resistant to acids and alkalines and can handle 95% of common chemicals. This means our clamps won’t break down when directly exposed to these substances, including moisture, which can cause rust and corrosion. They don’t show any signs of wear or chemical changes. This clamp remains in good condition, even in harsh environments, making it last longer and stay reliable. Our V-BAT™ Pipe Clamp is completely corrosion and chemical-resistant, preventing damage like pitting, material weakening, and mechanical failure. There’s no need for corrosion-resistant materials or protective coatings.

Cost-Effective: At just $2.49 per clamp, the V-BAT™ is an affordable option that saves you money compared to Universal-Sized Pipe Clamps. Its low price and high durability help professionals save money, making the V-BAT™ Pipe Clamp the best choice. This cost-effectiveness makes it a smart investment for anyone needing reliable pipe clamps.

Certifications: Our UNICLAMP V-BAT™ Pipe Clamp is certified by UL2239, UL2043, ISO, RoHS, Reach, and Branz, providing confidence and assurance.

Real-World Applications of the UNICLAMP V-BAT™ Pipe Clamp

The V-BAT™ has been successfully implemented across a wide range of industries, demonstrating its versatility and effectiveness:

- HVAC Systems

- Plumbing

- Industrial Pipelines

- Breweries

- On and Offshore Drilling

- Cement Industries

- Gas and oil Plants

- Underground Coal mining

- Automotive manufacturing

In practicality, anywhere pipelines need fastening, our UNICLAMP V-BAT™ Pipe Clamp is the only required clamp.

Why Choose the UNICLAMP V-BAT™ Over Universal-Sized Pipe Clamps?

Try us out completely risk-free! We offer a 5-year warranty on any quality-related defects. Plus, we’re so sure that Uniclamp will improve your plumbing business that we give you 365 days to test it out! If you are not happy with our products, just contact us—we’ll pay for the return shipping and give you a full refund!

Conclusion

Our UNICLAMP V-BAT™ Pipe Clamp is better than traditional Universal-Sized Pipe Clamps because it is strong, fits more pipe sizes, and uses metal zip ties for extra strength and durability. The V-BAT™ makes installation easier and offers a more secure and reliable solution, especially in tough environments where regular clamps do not work well.

Visit Uniclamp USA to learn more about our V-BAT™ and place your order today. Don't settle for less—choose our V-BAT™ and ensure all your projects are completed with the highest quality and reliability level.