Utilizing The Uniclamp and V-BAT™ Pipe Clamps in Breweries

Brewing is a detailed and carefully controlled process that requires attention to detail and adherence to safety protocols to produce high-quality beer and maintain a safe working environment. This industry demands high levels of efficiency and reliability in its operations. The infrastructure supporting these activities must be robust and versatile, from transporting raw materials to the meticulous brewing process. Our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp are necessary tools in the Brewing Industry. These UNICLAMP USA products are designed to meet the rigorous demands of the brewing industry.

Universal Fit and Compatibility Of Our Uniclamps

Our UNICLAMP Strut and V-BAT™ Pipe Clamp are designed to allow a wide range of pipe sizes, from 3/8" to 5" (9mm up to 127mm)

Our UNICLAMP Strut and V-BAT™ Pipe Clamp’s design makes it compatible with an assortment of pipe materials, from stainless steel, and copper to PVC, making it an ideal choice for breweries. This compatibility ensures that the same clamp can be used throughout the facility, simplifying inventory. Whether they are used for small lines carrying cleaning solutions or larger pipes transporting beer, Our UNICLAMP Strut and V-BAT™ Pipe clamps can handle it.

Ease of Installation

In a busy brewery, where time is of the essence, being able to secure pipes with minimal tools quickly is a significant advantage.

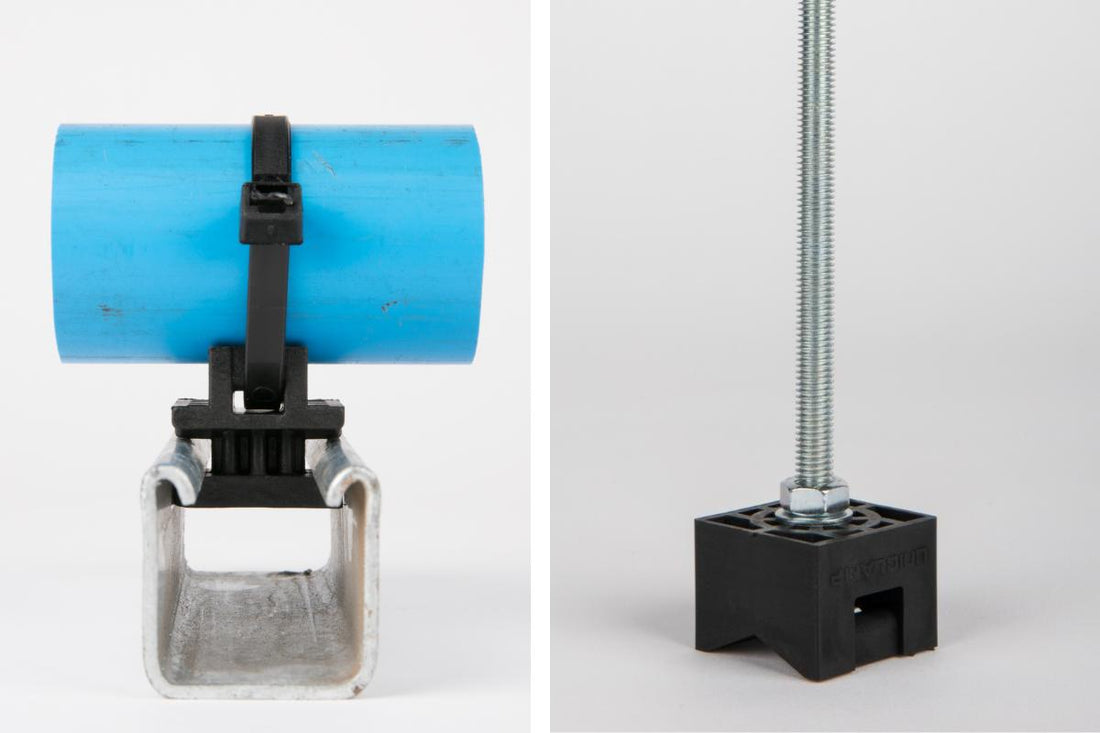

V-BAT™ Pipe Clamp

In the brewing industry, efficiency is crucial. Our V-BAT™ Pipe Clamp is designed for quick installation with Hilti guns, ensuring no signs of stress, cracks, or weakening, making it perfect for heavy-duty applications. Installation is simplified with a socket wrench or ratchet, cutting labor costs and saving time. The clamp offers versatile four-way applications: it can be used on flat surfaces, as a universal hanger, as a spacer, and for Unistrut fixtures, demonstrating its adaptability and robustness for various needs.

Purchase Our V-BAT™ Pipe Clamp and streamline your project today!

UNICLAMP Strut Pipe Clamp

Speed of Installation

Our UNICLAMP Strut Pipe Clamp significantly cuts installation time by up to 83% compared to conventional clamps. Its tool-free, easy-to-use place, twist, and strap interlocking system makes it a cost-effective option for various projects. Additionally, Our HDPE sleeve is available to protect pipes from insulation damage, ensuring durability and efficiency in all installations.

Get Your Free Shim Today with Every Uniclamp Strut Pipe Clamp Purchase!

High Durability and Longevity

Our UNICLAMP Strut and V-BAT™ Pipe Clamp are made from 30% glass-reinforced nylon 6.6, offering tensile strengths of 900 lbs and 1100 lbs, respectively. Our clamps are designed to endure extreme conditions and are rust-proof, waterproof, acid-proof, and corrosion-resistant. They also exhibit excellent wear resistance and dimensional stability, making them ideal for humid and corrosive environments like breweries. This durability ensures fewer replacements and lower maintenance costs, with a UV-resistant lifespan of 15-20 years, even in harsh conditions.

Secure Strapping Pipe Installation

Heavy-duty strapping is essential for stable pipe installations, we offer Stainless Steel Zip Ties capable of supporting up to 200 lbs based on installation needs. Our UV-stabilized Nylon zip ties, made from nylon 6.6, offer a carrying capacity of up to 175 lbs. Additionally, our UNICLAMP Strut Pipe Clamp and V-BAT™ Pipe Clamp ensure that pipes are securely held in place, which is vital for the brewing industry. These clamps and ties are designed for maximum reliability and strength, maintaining steadiness in demanding environments.

Explore Our Range of Uniclamp Products here.

Temperature Resistance

Maximum temperatures of 572°F (300°C) qualify our UNICLAMP strut and the V-BAT™ pipe clamps to be used in the brewing environment.

Chemical Exposure

Our clamps resist acid and 95% of common chemicals, ensuring no deterioration when exposed to alkalis and acids. They show no observable degradation or permanent chemical changes, maintaining their integrity and performance even in harsh environments.

Certifications

Our UNICLAMP Strut and V-BAT™ Pipe Clamp are certified by UL2239, UL2043, ISO, RoHS, Reach, and Branz, ensuring confidence in Our Uniclamp products.

Our Uniclamp Strut Pipe Clamp and V-BAT™ Pipe Clamp

Our UNICLAMP Strut and V-BAT™ Pipe Clamp are highly versatile products securing pipes, conduits, and tubing to various structures. Here’s how it is typically employed in breweries:

Piping Systems Installation: Breweries rely on extensive piping systems to transport water, wort, beer, and cleaning agents throughout the facility. Our UNICLAMP Strut and V-BAT™ Pipe Clamp provide a reliable method to secure these pipes to walls, ceilings, and floors. Our Clamp's robust construction ensures that pipes remain securely in place, preventing leaks and maintaining the system's integrity.

Easy Adjustments: Our UNICLAMP Strut and V-BAT™ Pipe Clamp offer the flexibility needed for easy adjustments, which is crucial in brewery settings where process changes may require repositioning or adding new piping. Their design and functionality allow for modifications without causing extensive downtime.

Safety and Efficiency in Breweries

The safety and efficiency of the brewing process are paramount. Both the UNICLAMP Strut and the V-BAT™ Pipe Clamp contribute significantly to these aspects in several ways:

Leak Prevention: Properly secured pipes minimize the risk of leaks, which is essential for maintaining beer quality and consistency. Preventing leaks also enhances safety and conserves valuable resources.

Ease of Maintenance: These clamps facilitate quick and efficient maintenance of brewery pipes and equipment, reducing downtime and ensuring smooth operations. UNICLAMP pipe clamps are maintenance-free.

Strength and Reliability: The robust design of the UNICLAMP Strut and V-BAT™ Pipe Clamps withstands demanding brewery conditions, ensuring safe and functional infrastructure, and protecting both the product and personnel.

Corrosion Resistance: Designed to handle humid environments and chemical exposure, our UNICLAMP clamps excel in brewery settings.

Materials Used for Piping in Breweries

Stainless Steel: The most common material used due to its resistance to corrosion, durability, and ease of cleaning.

Copper: Used for certain heat exchangers but less common due to its reactivity with acidic solutions.

PVC and CPVC: Used for specific applications, such as water lines, but not typically for wort or beer due to potential leaching and lower temperature resistance.

Investigating Corrosiveness in the Brewery Process:

Cleaning Agents: Breweries use strong alkaline and acidic cleaners to sanitize equipment. Common chemicals include caustic soda (sodium hydroxide) and nitric/phosphoric acid blends. These agents are highly corrosive, particularly to certain metals.

Wort and Beer: The wort (unfermented beer) and beer have low pH levels. This acidity can be mildly corrosive over time, especially to metals not specifically designed to resist acidic environments.

Water Treatment Chemicals: Chlorine and other disinfectants used in water treatment can also be corrosive.

Carbon Dioxide: CO2 gas is released through the fermentation process. When combined with water it forms carbonic acid, which is highly corrosive to metals and copper.

pH Levels in the Brewery Process

The pH scale runs from 1 to 14, with 1 being the most acidic and 14 the most basic, 7 is neutral.

- Mash: pH around 5.2 to 5.6.

- Wort and beer: pH drops to around 4.0 to 5.2.

- Fermentation: pH of beer between 4.0 to 5.0.

- Cleaning Solutions: Can have pH levels from very acidic (2.0-3.0) to highly alkaline (11.0-13.0).

Acid and Alkaline Corrosion

The most common type of acidic corrosion is rust and Alkaline corrosion can be particularly damaging to aluminum and magnesium alloys. The corrosion process can cause pitting, which can weaken the metal and cause it to fail.

Temperature and Pressure

- Mashing: Conducted between 143°F to 162°F (62°C to 72°C)

- Boiling: Generally at 212°F (100°C).

- Fermentation: Depends on the yeast used:

- Ale yeast: 59°F to 75°F (15°C to 24°C)

- Lager yeast: 45°F to 55°F (7°C to 13°C)

- Conditioning: Varies widely, often at cool temperatures, around 32°F to 39°F (0°C to 4°C)

Pressure is primarily a concern during the fermentation process. The production of carbon dioxide creates pressure in the fermentation vessel. Fermentation tanks are designed to withstand this pressure, and safety valves are used to release excess pressure.

The materials used in manufacturing our UNICLAMP Strut and V-BAT™ Pipe Clamps are resistant to corrosion, acids, chemicals, and pitting, withstanding heat and pressure, ensuring long-term performance and reducing the risk of failures that could lead to accidents or production halts.

Conclusion

In conclusion, Our UNICLAMP Strut and V-BAT™ Pipe Clamps are indispensable tools in the brewery industry. Their versatility, durability, and ease of installation make them ideal for securing the extensive piping systems required in a brewery. By ensuring that pipes are securely fastened, these clamps help maintain the efficiency and safety of the brewing process. Whether it’s the initial installation or ongoing maintenance, the use of these high-quality clamps from UNICLAMP USA contributes significantly to the smooth operation and success of a brewery.

Discover how Our Uniclamp Strut & V-BAT™ Clamps boost brewery efficiency and safety. Our durable clamps ensure secure installations, meeting rigorous industry demands.